Food safety is a question of key importance within the food industry—to make certain that products are safe for consumption and meet regulatory standards. Food safety audits examine each aspect of food production and handling and check it against systemic safety factors. This comprehensive guide will further elaborate on the importance, types, and steps involved in food safety audits while focusing on how SGS Digicomply can make this process easier and better.

What is a Food Safety Audit?

A food safety audit implies a detailed inspection of food businesses in regard to food safety standards and regulations. This systematic evaluation comprises each area and procedure in the handling and production chain in food establishments, pointing out potential risks and areas for improvement.

Key Objectives of a Food Safety Audit:

- Compliance Verification: Ensuring adherence to food safety laws and regulations.

- Risk Identification: Detecting hazards within food production processes.

- Continuous Improvement: Offering recommendations for enhancing food safety practices.

- Consumer Protection: Guaranteeing that food products are safe and meet quality standards.

Components of a Food Safety Audit:

- Documentation Review: Examination of records like HACCP plans, training logs, and sanitation procedures.

- On-site Inspection: Physical check of facilities, equipment, and processes for compliance.

- Interviews and Observations: Engaging with staff to assess their knowledge and implementation of food safety practices.

- Reporting: Detailed report highlighting findings, non-conformities, and improvement recommendations.

Types of Food Safety Audits

Food safety audits can be categorized depending on the party who undertakes them and the objective of the audit. Using these identification helps to ensure that food safety management is all-inclusive.

Internal Audits

Internal audits are conducted by the food business's own staff or appointed internal auditors. These audits are supposed to evaluate and improve the business's internal processes and to continue complying with the requirements set out in the food safety standards. They help to be proactive and head off potential issues before they turn out to be a big deal.

External Audits

External audits are conducted by an independent body from the food business itself. They may further be classified into:

- First-party Audits: Conducted internally by the business’s own employees to assess their food safety systems and identify areas for improvement. They help ensure readiness for external audits.

- Second-party Audits: Also known as proprietary audits, these are conducted by the food business on its suppliers or other related businesses. They evaluate the effectiveness of the supplier’s food safety management systems and ensure they meet the necessary standards.

- Third-party Audits: Conducted by independent auditors or food auditing firms. These audits provide an objective assessment of the food business’s compliance with regulatory standards and are often required for obtaining certifications like ISO 22000 or BRCGS.

Importance of Each Audit Type

- Internal Audits: Promote continuous improvement and prepare the business for external and regulatory audits.

- First-party Audits: Ensure the business’s own food safety systems are effective and compliant.

- Second-party Audits: Evaluate suppliers to ensure they meet required standards, thereby protecting the business’s supply chain.

- Third-party Audits: Provide independent verification of compliance, necessary for certifications and enhancing credibility.

Importance of Food Safety Audits

Food safety audits are important for a variety of reasons, not only in maintaining but also in enhancing the safety and quality of food products.

COMPLIANCE ENSURED

Food safety audits are carried out to ascertain if a business complies with the set local, national, and international food safety regulations. Compliance is very critical in avoiding legal penalties, maintaining licenses, and ensuring consumer confidence.

RISK IDENTIFICATION AND MITIGATION

Audits trace the occurrence of potential hazards all through the production cycle—from raw material handling to the final product delivery. The identification of these risks allows companies to take proactive steps toward reducing the risk of contamination and foodborne illness.

IMPROVING FOOD SAFETY MANAGEMENT SYSTEMS

Regular audits also allow an understanding of how effective a business's food safety management system has been. They point out what can be improved and also provide recommendations for best practices, which helps to inculcate the concept of continuous improvement in the culture of the organization.

REINFORCING BRAND REPUTATION

Passing food safety audits, more so third-party and certification audits, actually increases the reputation of the company. It means that the company has a regard and commitment to high standards of food safety, which often is a very effective marketing tool in the market competition.

CONSUMER CONFIDENCE BUILDING

It is obvious that consumers would be more trusting of products from companies with a clean record of food safety. Regular audits and certifications give assurance to the consumer that the product being placed on shelves for buying is safe to consume and of quality.

Key Areas of a Food Safety Audit

A food safety audit covers several critical areas to ensure comprehensive evaluation and compliance with food safety standards.

Hygiene and Sanitation Practices

- Personal Hygiene: Assessing staff hygiene practices, including handwashing and proper use of protective clothing.

- Facility Cleanliness: Checking the cleanliness of the production and storage areas to prevent contamination.

Hazard Analysis and Critical Control Points (HACCP)

- Hazard Identification: Identifying potential biological, chemical, and physical hazards in the food production process.

- Critical Control Points (CCPs): Verifying the implementation and monitoring of CCPs to control identified hazards.

Documentation and Record-Keeping

- Compliance Records: Reviewing records of compliance with food safety regulations and standards.

- Process Documentation: Ensuring that all processes are documented and traceable.

Staff Training and Competence

- Training Programs: Evaluating the effectiveness of food safety training programs for staff.

- Competence Verification: Ensuring that employees understand and correctly implement food safety practices.

Equipment and Facility Maintenance

- Equipment Sanitation: Checking that all equipment is regularly cleaned and sanitized.

- Facility Upkeep: Ensuring the facility is well-maintained and conducive to safe food production.

Essential Food Safety Audit Steps

Conducting a food safety audit involves several critical steps to ensure a thorough evaluation and compliance with food safety standards.

1. Planning and Preparation

- Define Scope and Objectives: Determine the audit's scope and specific objectives.

- Gather Documentation: Collect all relevant documents, such as HACCP plans, SOPs, and previous audit reports.

2. Conducting the Audit

- Initial Meeting: Hold a kickoff meeting with key personnel to outline the audit process.

- On-site Inspection: Perform a physical inspection of the facilities, equipment, and processes.

- Interviews and Observations: Engage with staff to assess their understanding and implementation of food safety practices.

3. Reporting Findings

- Non-conformities: Identify and document any deviations from food safety standards.

- Recommendations: Provide actionable recommendations to address non-conformities and improve processes.

4. Implementing Corrective Actions

- Action Plan: Develop a plan to address identified issues, including timelines and responsibilities.

- Follow-up: Monitor the implementation of corrective actions to ensure they are effective.

5. Follow-up Audits

- Verification: Conduct follow-up audits to verify that corrective actions have been successfully implemented.

- Continuous Improvement: Use audit findings to continuously improve the food safety management system.

How to Prepare for a Food Safety Audit

The preparation phase before the actual food safety audit is very critical, and there are steps that one needs to follow for it to be smooth and successful. The detailed ways of getting prepared are presented as follows:

1. GATHER NECESSARY DOCUMENTATION

First, make sure you have gathered all key documents such as the HACCP plans, SOPs, training records and preceding audit reports. Be sure that such documents are current and an accurate representation of current practices. A checklist will enable one to track all needed documents and their status.

2. INTERNAL PRE-AUDITS

Conduct internal audits for potential problems or areas of improvement. This kind of pre-audit will provide simulation of the real audit process, thus giving you a chance to identify and correct non-conformities in advance. Internal audits will also make your team more familiar with the audit process, which will reduce their anxiety levels and genuinely prepare them for the audit.

3. TRAIN YOUR STAFF

Ensure that all staff are properly trained in the area of food safety, aware of their role in case of an audit, and undertake refresher training in relation to critical control points, hygiene practices, and documentation procedures. Assist staff to respond confidently and accurately to auditor questions.

4. MANAGE AREAS OF POTENTIAL NONCOMPLIANCE

Identify deficiencies or non-compliances in food safety and corrective action. This would include, but not be limited to, ensuring the cleanliness and operability of equipment, accuracy, and completeness of all records, and gaps in staff training. Corrective actions are taken and improvements documented.

5. PREPARING FOR THE AUDIT DAY

Plan out the detailed program of the audit day and who will be responsible for each part of the process. All the required personnel should be available, and areas for the audit should be easily accessible. Having a well-organized plan shows your commitment toward food safety and also helps in ensuring that the audit runs smoothly.

Additional Tips for a Successful Audit

- Communication: Maintain open lines of communication with the auditor. Be transparent about your processes and any challenges you face.

- Documentation: Keep all documents well-organized and easily accessible. Use a digital system if possible to streamline the process.

- Attitude: Approach the audit as an opportunity for improvement rather than a punitive exercise. Encourage your team to view it positively.

What is a Food Safety Auditor?

The food safety auditor is the person who assumes a critical function in ascertaining that food businesses involved do follow the concerned food safety standards and regulations. He or she shall evaluate whether the company's food safety management system is effective and pinpoint areas for improvement.

Qualifications and Skills

Food safety auditors primarily hail from the food science or microbiology disciplines. A number of them have completed certification programs, such as Certified Food Safety Auditor or ISO 22000 Lead Auditor. Their desirable skills and qualities include a detail-oriented mindset, analytical thinking, good communication skills, and a good working knowledge of food safety regulations and standards.

Responsibilities

- Pre-Audit Preparation: Reviewing the company’s documentation, previous audit reports, and understanding the scope of the audit.

- On-site Evaluation: Conducting thorough inspections of the facility, including equipment, storage areas, and production processes. This involves observing hygiene practices, checking for compliance with HACCP plans, and ensuring that all procedures align with regulatory requirements.

- Interviews and Observations: Engaging with staff to assess their knowledge and implementation of food safety practices. Auditors observe daily operations to verify that documented procedures are being followed correctly.

- Data Analysis and Reporting: Compiling findings into a detailed audit report. This report outlines any non-conformities, suggests corrective actions, and provides recommendations for improving the FSMS.

- Follow-Up: Auditors may conduct follow-up audits to ensure that corrective actions have been implemented effectively. This helps in maintaining continuous improvement within the food business.

The Audit Process

The audit process typically starts with an opening conference wherein the auditor introduces the nature and objectives of the audit. This is followed by actual inspection, interviews, and documentation review. The process concludes with a closing meeting where the auditor presents preliminary findings and discusses probable corrective actions to be addressed by management.

Importance of a Food Safety Auditor

Food safety auditors play a critical role in upholding high standards in the food industry by helping a business identify and deal with risks, comply with regulations, and promote continuous improvement. Objective assessment by auditors enhances overall food safety and quality of products, thereby protecting public health and enhancing consumer confidence.

Useful Food Safety Auditing Tools

Food safety auditing involves the application of various tools that help to facilitate the process and ensure comprehensiveness and accuracy. Following are some of the key tools that can assist in conducting an effective food safety audit:

1. Checklists and Templates

The audit checklists and templates help in covering all the critical areas for the audit. They provide a structured way of going about it, thus making them easier to track in terms of compliance with certain set standards and regulations. The commonly used checklists include hygiene practices, cleaning regimes, equipment maintenance, and HACCP compliance.

2. Digital Auditing Software

Software solutions like SGS Digicomply offer digital tools that simplify the auditing process. These tools allow auditors to:

- Digitize Documentation: Maintain and access all necessary documents electronically, reducing the risk of lost paperwork.

- Real-time Data Collection: Use mobile devices to record observations and findings on-site, ensuring accuracy and efficiency.

- Automated Reporting: Generate comprehensive audit reports quickly, highlighting non-conformities and suggesting corrective actions.

3. Data Analytics Tools

Data analytics tools help auditors analyze trends and identify recurring issues. By examining historical data, auditors can pinpoint areas that require more attention and develop strategies for continuous improvement.

4. Compliance Management Systems

These systems help manage compliance with various food safety standards and regulations. They offer features such as:

- Regulatory Updates: Stay informed about the latest changes in food safety regulations.

- Task Management: Assign and track corrective actions to ensure timely resolution of identified issues.

5. Training Modules

Training tools ensure that all staff members are knowledgeable about food safety practices. Online training platforms can provide interactive courses and assessments to keep staff updated on the latest standards and procedures.

6. Mobile Inspection Apps

Mobile apps designed for inspections allow auditors to conduct audits on-the-go. These apps often include features such as:

- Photo Documentation: Capture and attach photos to audit findings for better evidence and clarity.

- GPS Tracking: Verify the location of inspections to ensure comprehensive coverage of all facilities.

How SGS Digicomply Enhances Food Safety Audits with AI

SGS Digicomply food safety & regulatory compliance software offers a comprehensive suite of AI-driven tools designed to streamline and enhance food safety audits. These tools help businesses ensure compliance, manage risks, and improve overall food safety management.

Here are the key features and their respective demos:

-

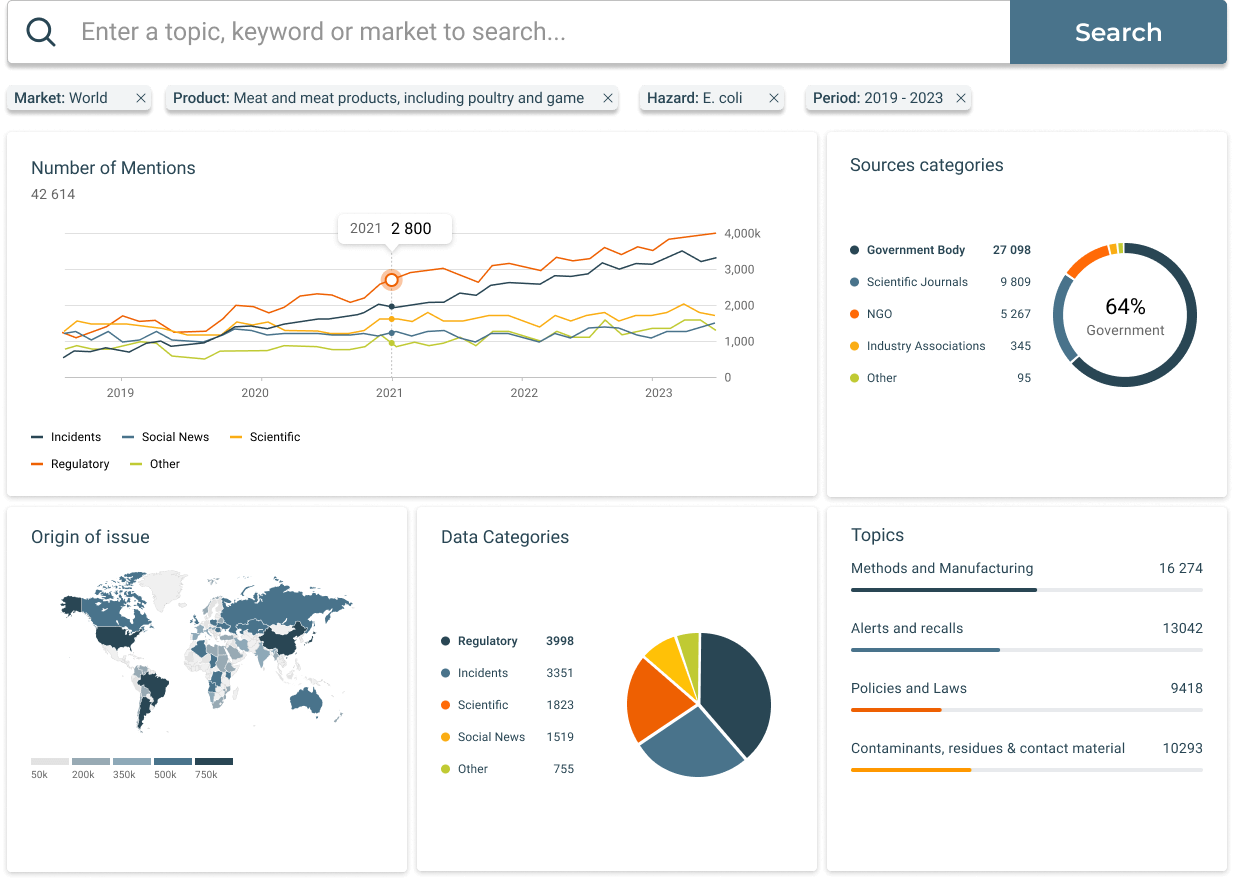

Food Safety Intelligence: Monitors global alerts and recalls, providing early detection of hazards. Watch demo

-

Food Safety Incidents: Distills key trends and insights from source posts for a comprehensive understanding of food safety issues. Watch demo

-

Regulatory Change Management: Uses AI to monitor and analyze regulatory changes, offering up-to-date insights and helping businesses stay compliant. Watch demo

-

Food Fraud Insights: Integrates diverse data types to identify patterns and emerging risks, enabling proactive measures against food fraud. Watch demo

-

Regulatory Research: Translates regulatory documents into English and provides summaries, aiding in decision-making and regulatory navigation. Watch demo

-

Regulatory Agenda: Lists and analyzes regulatory deadlines, ensuring businesses stay informed and compliant. Watch demo

-

Policies and Regulations: Explores global policies, emphasizing early detection of emerging trends and regulatory changes. Watch demo

-

Regulatory Analytics: Provides insights into legislative changes and compares regulatory requirements across multiple markets. Watch demo

-

Supply Chain Intelligence: Monitors suppliers and alerts businesses about mentions in food safety content. Watch demo

-

Food Safety Foresight: Uncovers insights from scientific publications, identifying emerging hazards and helping businesses navigate the food safety landscape. Watch demo

-

Regulatory Guides: Offers regulatory guides for countries worldwide, helping businesses navigate the regulatory landscape and ensure compliance. Watch demo

-

Ingredients Risks Monitoring: Filters incidents across various sources, providing comprehensive hazard overviews and AI-generated summaries. Watch demo

-

Restricted Substances - Contaminants MRLs Database: Streamlines substance searches and provides regulatory references within defined limits. Watch demo

-

Restricted Substances - Food Additives Database: Helps navigate regulations for food additives, ensuring thorough exploration and compliance. Watch demo

These tools provide comprehensive monitoring, analysis, and management capabilities that enhance the efficiency and effectiveness of food safety audits, ensuring businesses stay compliant and proactively manage risks.

FAQs

Food safety audits can get complicated, and definitely one is bound to have some questions regarding the same. Here are some of the frequently asked questions that help in the elucidation of common concerns and further insights into the same.

1. WHAT IS A FOOD SAFETY AUDIT FOR?

An audit in food safety ensures that the concerned business works within the regulatory standards, points out lacunae, and brings improvement in the practices of food safety. This aims to enhance overall safety and quality of the food products supplied to the consumers for consumption and satisfies legal compliance.

2. HOW OFTEN SHOULD FOOD SAFETY AUDITS BE CONDUCTED?

Food safety audits' frequency is decided by: the type of food business involved, requirements legally and through regulation, and level of risk associated with the products produced. As a general guideline, businesses should perform internal audits on a regular basis—e.g., quarterly or bi-annually—and prepare for an external audit when necessary, based on certification body or regulatory agency requirement.

3. WHAT HAPPENS IF NONCONFORMITIES ARE DETECTED DURING AN AUDIT?

In case of identification of non-conformities, the auditor will include them in the audit report, together with recommendations on corrective actions. After these, the food business shall develop and implement a corrective action plan. Follow-up audits might be carried out to make sure corrective actions have been effectively implemented.

4. HOW SGS DIGICOMPLY CAN ASSIST IN FOOD SAFETY AUDITS?

SGS Digicomply offers in its suite of tools and resources digital documentation management, real-time data collection, automated reporting, and continuous improvement tracking in order to smoothen the auditing process. SGS Digicomply provides companies with assistance on compliance with regulations, risk management, and food safety management systems.

5. WHAT QUALIFICATIONS SHOULD A FOOD SAFETY AUDITOR HAVE?

A food safety auditor shall be a graduate in food science, microbiology, or any other related stream. He shall be certified as CFSA—Certified Food Safety Auditor—or ISO 22000 Lead Auditor. The auditor shall possess an analytical mind, attention to detail, and full knowledge of the food safety standards and regulations.

6. WHY SHOULD FOOD SAFETY AUDITING BE OUTSOURCED TO THIRD PARTIES?

Third-party audits can be regarded as an independent assessment of the degree of compliance of a food business regarding food safety standards. They add to credibility, achieve certifications, and reassure consumers about maintaining high food safety standards within the business. Areas for improvement that may not turn up in internal audits may also be recognized by third-party audits.

7. HOW CAN A FOOD BUSINESS PREPARE FOR A REGULATORY AUDIT?

As preparation for a regulatory audit, so a food business is supposed to have its documentation up to date, perform an internal pre-audit, train its staff on what to expect during the audit, and resolve areas of possible non-compliance. It will also provide for appropriate planning of a detailed audit day schedule and ensure open communication with the auditor.

8. WHAT ROLE DOES TECHNOLOGY PLAY IN MODERN FOOD SAFETY AUDITS?

Technology today is indivisible from the food safety audit process, all the way from digital documentation tools to real-time data collection and automated reporting. Efficiency, accuracy, and compliance, through stitching under one umbrella the different constituents of the auditing process with SGS Digicomply platforms, become a reality.

9. CAN FOOD SAFETY AUDITS HELP IMPROVE CUSTOMER TRUST?

Yes, frequent and comprehensive food safety audits convey a strong message of high standards and continuous improvement to customers, which will raise their level of trust. Certifications issued subsequent to successful third-party audits can also be used for quality assurance in the consumer's view.

10. WHAT ARE SOME COMMON CHALLENGES IN FOOD SAFETY AUDITS?

Common problems include keeping documents current, maintaining food safety practices among personnel, managing corrective actions, and dealing with regulatory change. You can master these challenges, or at least reduce their intensity, by applying the help of complete and structured tools such as SGS Digicomply.

.webp?width=1644&height=1254&name=Food%20Safety%20Dashboard%201%20(1).webp)