Chicken is one of the most widely consumed meats worldwide, making food safety in its production and distribution critical. Chicken recalls are frequently triggered by contamination with harmful pathogens such as Salmonella and Campylobacter, or by foreign material presence, mislabeling, and other quality control issues. Because of the widespread consumption of chicken, recalls are essential to protect public health and maintain trust in the food supply chain. This guide covers the main causes of chicken recalls, regulatory oversight, their impact on the poultry industry, and preventive measures for safer production practices. Let's dive into this type of Food Recall.

What is a Chicken Recall?

A chicken recall is the urgent removal of potentially unsafe or contaminated chicken products from the market. Recalls may be initiated voluntarily by producers or mandated by regulatory authorities like the USDA’s Food Safety and Inspection Service (FSIS) when health risks are identified. Recalls can affect various chicken products, including raw cuts, processed items, and ready-to-eat (RTE) products. Given the significant health risks associated with contaminated chicken, recalls are managed with high urgency to protect consumers from potential illness.

Main Causes and Hazards of Chicken Recalls

Chicken recalls typically result from the following hazards, each posing unique health risks to consumers:

-

Bacterial Contamination (e.g., Salmonella, Campylobacter, Listeria): Bacterial contamination is the most common cause of chicken recalls. Salmonella and Campylobacter are particularly prevalent in poultry and can cause severe foodborne illnesses with symptoms ranging from abdominal pain to fever. Listeria contamination, although less common, can be especially dangerous for vulnerable populations and is often found in RTE chicken products.

-

Foreign Material Contamination (e.g., Plastic, Metal, Bone Fragments): Chicken recalls may also occur due to foreign materials in the product, such as plastic, metal shards, or bone fragments. These contaminants pose physical hazards, including choking and internal injury.

-

Improper Temperature Control and Spoilage: Correct temperature management during chicken production, storage, and transport is essential to prevent bacterial growth. If products are improperly handled or stored, they may spoil or become unsafe, leading to recalls.

-

Allergen Mislabeling: Processed chicken products may contain allergens like soy or dairy. If these allergens are not properly declared on the label, it poses serious health risks to consumers with allergies and necessitates a recall.

Each of these hazards emphasizes the importance of rigorous safety and quality control throughout chicken production and distribution.

Regulatory Authorities' Role in Chicken Recalls

In the United States, the USDA FSIS oversees chicken recalls, with the CDC potentially involved in tracking and managing outbreaks linked to contaminated poultry. Key responsibilities of regulatory authorities include:

-

Inspection and Monitoring: FSIS inspects poultry processing facilities to ensure compliance with hygiene, temperature control, and quality assurance standards. These inspections focus on controlling contamination risks throughout the production process.

-

Recall Classification and Management: When a recall is necessary, FSIS classifies it based on risk:

- Class I Recall: High risk, involving products that could cause severe health issues or death, such as chicken contaminated with Salmonella or Listeria.

- Class II Recall: Moderate risk, where the product may cause temporary health issues but is unlikely to lead to severe illness.

- Class III Recall: Low risk, involving products that violate labeling or regulatory standards without posing immediate health threats.

-

Testing and Surveillance: FSIS and USDA conduct regular testing on chicken products for pathogens like Salmonella, Campylobacter, and Listeria to detect contamination early. Proactive monitoring helps identify issues before products reach consumers.

-

Public Communication and Alerts: When a recall is initiated, FSIS issues public alerts that provide information on affected products, lot numbers, and safety risks. This public communication ensures that consumers are informed and can take necessary precautions.

-

Corrective Actions and Compliance: After a recall, FSIS may require companies to implement corrective actions, such as improving sanitation protocols, enhancing allergen labeling accuracy, or upgrading equipment. These measures help prevent future recalls and strengthen food safety practices.

The involvement of regulatory authorities ensures that chicken recalls are conducted effectively and transparently, safeguarding public health and upholding industry standards.

Impact of Chicken Recalls on the Industry

Chicken recalls can have far-reaching impacts on poultry producers, distributors, and retailers. Key effects include:

-

Financial Losses: Recalls lead to direct costs associated with retrieving products, conducting tests, and implementing corrective actions. Additional financial impacts may include lost sales, reduced consumer demand, and potential legal liabilities if consumers are harmed.

-

Reputation Damage: A chicken recall, especially one related to bacterial contamination, can significantly damage a brand’s reputation. Rebuilding consumer trust often requires transparency, a commitment to improved safety, and public relations efforts.

-

Increased Regulatory Scrutiny: Following a recall, companies often face heightened regulatory oversight, with more frequent inspections and additional compliance requirements. This increased scrutiny can strain resources and affect day-to-day operations.

-

Supply Chain Disruption: Chicken recalls impact the entire supply chain, from farms to retailers. Effective coordination is essential to ensure that affected products are removed and safe products are quickly made available to consumers.

Understanding these impacts highlights the importance of preventive measures to maintain food safety standards and protect consumer trust.

Preventive Measures for Chicken Recalls

To reduce the likelihood of chicken recalls, producers and processors should adopt proactive safety measures at every stage of production. Key preventive practices include:

-

Hazard Analysis and Critical Control Points (HACCP) Implementation: A robust HACCP plan identifies critical control points in chicken processing, allowing for effective prevention of contamination risks.

-

Sanitation and Hygiene Protocols: Strict sanitation practices throughout processing facilities help prevent bacterial contamination and cross-contamination. Regular cleaning of equipment, tools, and surfaces is essential for minimizing contamination risks.

-

Temperature Control and Cold Chain Management: Maintaining proper cold chain management during production, storage, and transport prevents bacterial growth. Consistent temperature monitoring helps ensure that chicken products remain safe and high quality.

-

Supplier Verification and Raw Material Testing: Working with trusted suppliers and conducting regular testing on raw materials helps ensure quality and minimize contamination risks from the source.

-

Routine Microbial Testing: Regular microbial testing of chicken products at various stages of production facilitates early detection of contaminants. Combined with batch tracking, this allows for swift action if contamination is detected.

-

Employee Training on Food Safety: Properly trained employees who understand food safety protocols, including hygiene and handling practices, help reduce contamination risks and maintain consistent safety standards.

-

Accurate Labeling and Allergen Management: Ensuring that all ingredients and allergens are properly declared on labels helps protect consumers with food allergies. Correct labeling and allergen control reduce the risk of mislabeling-related recalls.

By implementing these preventive measures, chicken producers can reduce recall risks, protect public health, and maintain regulatory compliance.

Conclusion

Chicken recalls are essential for protecting public health by addressing contamination risks, foreign materials, and labeling errors. Understanding the causes of chicken recalls—such as bacterial contamination, temperature control issues, and mislabeling—enables industry professionals to implement proactive safety measures that align with USDA FSIS standards.

For chicken producers, the key to effective recall management lies in prevention. Rigorous adherence to HACCP protocols, strict sanitation practices, and regular microbial testing are critical for minimizing contamination risks. Transparent communication with regulatory authorities and the public further reinforces consumer trust and supports a reliable food supply.

Last Month's Food Recalls and Safety Incidents

Explore the latest food recalls, market withdrawals, and safety alerts in our free Food Safety Incidents Dashboard. Updated monthly and powered by SGS Digicomply, this dashboard provides a clear, filterable list of last month’s global food recalls and incidents, allowing you to stay informed on the products and hazards affecting the industry.

How manufacturers and companies can track and utilize global recall data:

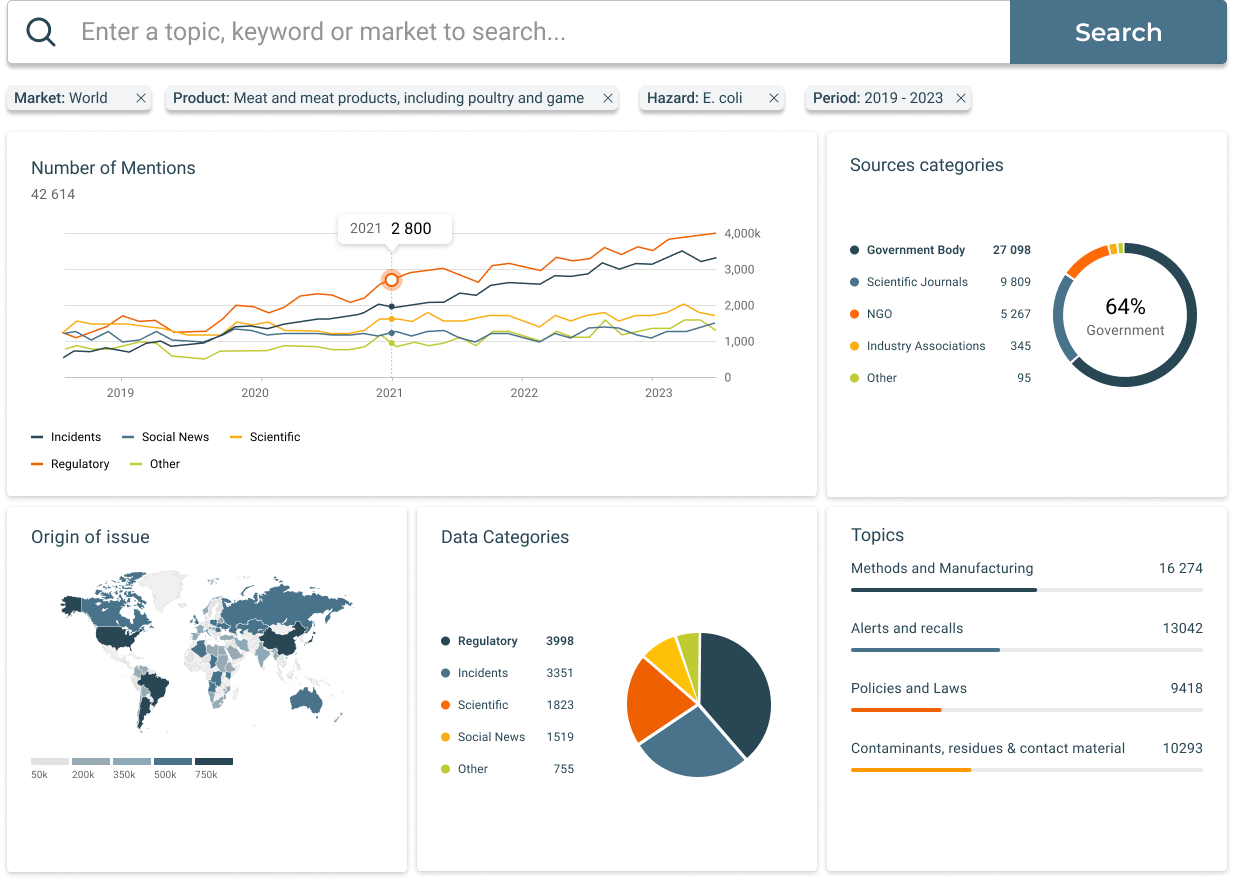

SGS Digicomply continuously monitors and analyzes millions of data sources across over 160 jurisdictions. With easy-to-use filters for sources, locations, products, substances, hazards, and more, our platform allows manufacturers to track recall trends and gain actionable insights powered by AI-Copilot.

Explore our interactive demos to see these tools in action.

By combining diverse data sources, SGS Digicomply offers the most comprehensive and targeted screening of food safety data, contextualized with real-time lab data to identify emerging risks.

.webp?width=1644&height=1254&name=Food%20Safety%20Dashboard%201%20(1).webp)