Food safety remains in the foreground of concerns for the food industry due to the latent health risks that foodborne hazards pose to consumers. Foresight scanning of food hazards is essentially a proactive way of identifying and mitigating these risks before actualization into critical issues. The technique includes continuous monitoring and analysis of possible hazards in the food supply chain all the way from production to consumption.

Through the adoption of foresight scanning, companies could monitor and deal with imminent, emerging risks related to product safety and quality. This helps not only to protect consumers but also benefits the company in issues related to brand reputation and compliance.

What is Foresight Scanning in Food Safety?

Food safety foresight scanning is a process of proactive identification and analysis of potential food hazards along the supply chain, involving forecasting and mitigation of risks before they become significant issues, to ensure production of food products that are safe and wholesome. This can be achieved through continuous monitoring of trends, emerging threats, and scientific advancements, thus allowing stakeholders in the food industry to maintain a lead over potential hazards.

This is an important part of public health protection and for the maintenance of reputation with regard to food companies, as well as adherence to the set standards by the regulatory bodies. This can enable organizations to apply their preventive measures, to take prompt remediation actions on identified risks, and thereby reduce the possibility of foodborne illness or contamination to a minimum.

Steps to Implement Foresight Scanning for Food Hazards

Implementing foresight scanning for food hazards requires a structured approach:

-

Identifying Potential Hazards:

- Start by mapping out the entire food supply chain, from production to consumption.

- Identify critical points where hazards are most likely to occur, such as during processing, packaging, and distribution.

-

Gathering Information:

- Collect data from a variety of sources, including scientific research, regulatory updates, industry reports, and global news.

- Use databases and monitoring tools to track emerging trends and potential hazards.

-

Analyzing Data:

- Employ data analytics to interpret the collected information and identify patterns or anomalies.

- Collaborate with food safety experts to understand the implications of the identified hazards.

-

Implementing Preventive Measures:

- Develop and implement strategies to mitigate the identified risks.

- Regularly update safety protocols and training programs based on the latest insights from foresight scanning.

Challenges in Foresight Scanning for Food Hazards

Despite the power this offers, a number of challenges are identifiable in scanning for hazards in food. One major challenge concerns the amount of data which must be monitored and analyzed. This can be overwhelming and requires sophisticated tools and expertise if it is to be managed effectively. Again, the complex nature of global food supply chains makes it increasingly difficult to trace all possible hazards.

The rapidly changing nature of food hazards also challenges them. New threats could come up at any time, and scanning processes updates and preventive measures are constantly required. Constraints of resources, mainly funding and manpower, also pose barriers to implementing comprehensive foresight scanning programs.

Advanced technologies and collaborative efforts by food industries, however, can resolve such problems. Application of AI and data analytics enables organizations to speed up the scanning process and get effective outcomes that help trace emerging hazards and perform a much better response.

The Role of AI in Enhancing Foresight Scanning for Food Hazards

Artificial Intelligence lies at the core in enhancing foresight scanning for food hazards. AI can gather electronically a large amount of data from various sources for analysis. The accuracy with real-time insight into potential risks is just huge. Machine learning algorithms adapted by these tools analyze these patterns and make predictions on future hazards so that proactive risk management could be assisted.

For example, AI can process data related to food safety across the globe to pinpoint emerging trends and possible threats. Distinctly, it can screen social media and news outlets for the first signs of foodborne outbreaks. Through natural language processing, AI interprets complex reports of a scientific or regulatory nature and extracts relevant information for further analysis.

AI in foresight scanning enhances the quality and speed of the process while covering, at the same time, a more comprehensive area of the food supply chain. This allows companies to stay ahead of threatening, rising factors and take preventive measures in a timely manner.

SGS Digicomply’s Approach to Foresight Scanning for Food Hazards

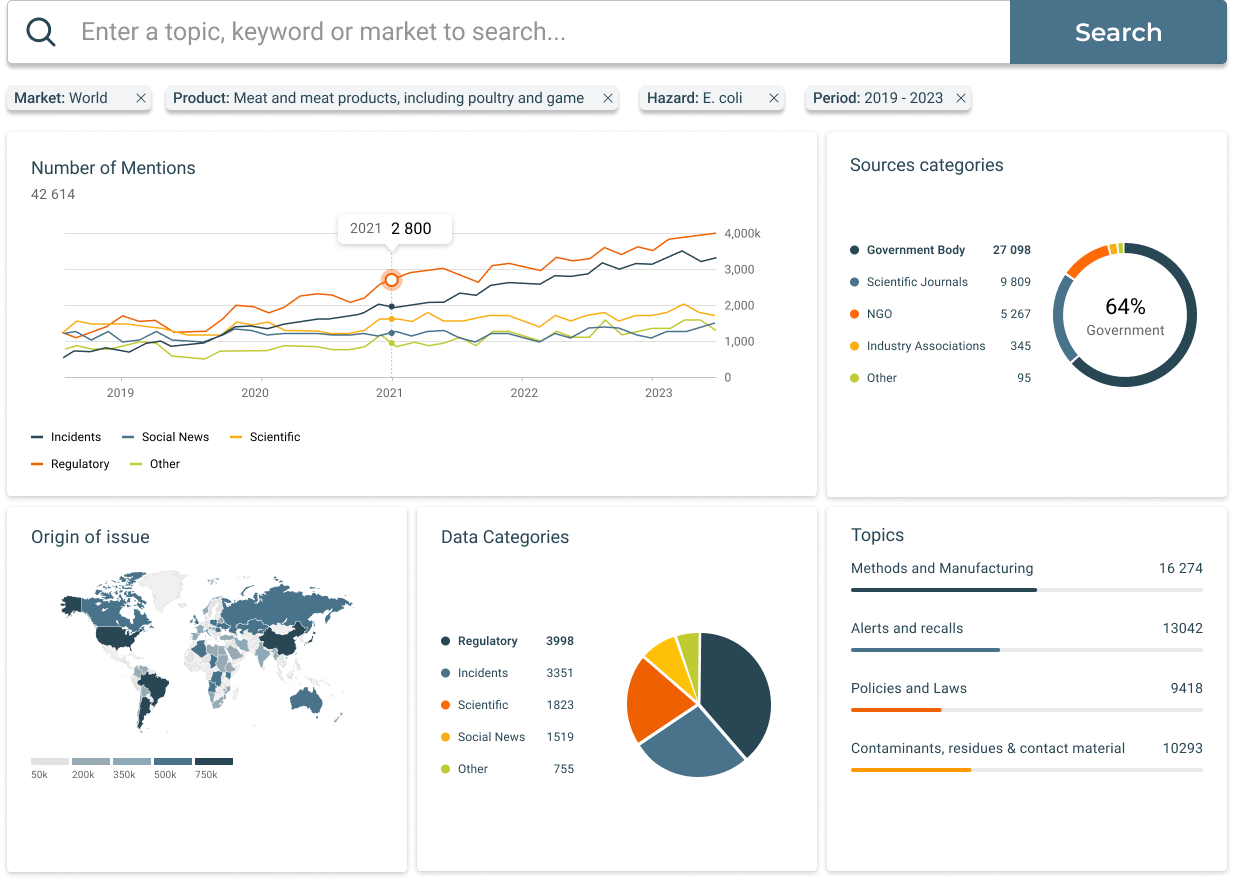

At SGS Digicomply, advanced AI is used to enhance the foresight scanning of food hazards. We have designed a one-of-a-kind platform for the proactive detection and analysis of possible food safety risks along supply chains. Using advanced data analytics and machine learning algorithms, our tools allow for tracking a vast array of diversified data sources for real-time insights into new threats.

The AI-powered system automates data collection and analysis, ensuring comprehensive coverage and precise risk assessments. This enables food industry stakeholders to implement timely preventive measures, maintain product quality, and ensure consumer safety. For more information, visit our Ultimate Guide to Horizon Scanning.

Future Trends in Foresight Scanning for Food Hazards

The future of foresight scanning in food hazards will be bright, going directly hand in hand with advancements made in technology. In the near future, Artificial Intelligence and Machine Learning will play an even more important role in the prediction and mitigation of risk, accompanied by the use of highly sophisticated algorithms and data analytics tools. Big data will enable deeper insights pertaining to global trends in food safety and more accurate risk assessments.

Cross-sector collaboration in the future will then play an important role, wherein such sharing of knowledge and best practice will increase the effectiveness of foresight scanning. These two, at the same time, will be attended by changing regulatory environments, driving forth the need for more efficient and agile scanning processes.

Food industry players are, therefore, better armed to deal with the fast pace of developments to ensure that their strategies safeguard their products against risks of safety and the future quality of the food chain.

Use leading-edge foresight scanning for food hazards to protect food safety and human health. Leveraging leading-edge technologies, proactive strategies, and state-of-the-art digital solutions for early warning identification and risk reduction means that organizations are positioned with the knowledge and capacity to stay ahead of emerging risks and maintain compliance with changing regulatory standards. The advanced tools and holistic approach of SGS Digicomply let organizations be proactive in getting ahead of the relevant risks and abide by the changing rules and regulations.

.webp?width=1644&height=1254&name=Food%20Safety%20Dashboard%201%20(1).webp)