In recent years, we have witnessed a significant surge in attention surrounding Polyvinyl Alcohol (PVA). For instance, according to data from SGS Digicomply - your All-in-one Food Safety & Regulatory Compliance platform, mentions of Polyvinyl Alcohol in scientific publications have experienced an extraordinary growth of 758% (2010-2023).

In this new food safety snapshot, our aim is to unravel the essence of Polyvinyl Alcohol, comprehend the driving forces behind the heightened interest surrounding it, and ascertain whether it genuinely holds the key to the future of eco-friendly sustainable packaging.

.png?width=2906&height=2254&name=Polyvinyl%20Alcohol%20Scientific%20Mentions%20Trend%20(2010-2023).png)

Intoduction

What is Polyvinyl Alcohol?

Polyvinyl Alcohol, commonly known as PVA, is a synthetic polymer derived from polyvinyl acetate through hydrolysis. This water-soluble polymer has gained prominence in various industrial applications due to its unique properties, including biodegradability and film-forming capabilities. As a versatile compound, PVA serves as a foundation for numerous products.

The Chemical Formula for Polyvinyl Alcohol (PVA)

The chemical formula for Polyvinyl Alcohol is represented as (C2H4O)n, where "n" denotes the degree of polymerization, indicating the number of repeating units in the polymer chain. The structure of PVA comprises repeating units of vinyl alcohol, derived from the hydrolysis of vinyl acetate.

How is Polyvinyl Alcohol Made

Polyvinyl alcohol is produced through a two-step process:

- Polymerization: Vinyl acetate monomers undergo polymerization to form polyvinyl acetate.

- Hydrolysis: Polyvinyl acetate is then hydrolyzed, typically under alkaline conditions, converting acetate groups into alcohol groups and resulting in polyvinyl alcohol.

What is Polyvinyl Alcohol Used For

Polyvinyl alcohol (PVA) is utilized in various industries for its versatile properties. Some key applications include:

- Adhesives: Key component in water-based adhesives.

- Textiles: Sizing agent for warp yarn in the textile industry.

- Paper: Coating agent for paper to enhance strength and printability.

- Packaging: Used in water-soluble films for packaging applications, including the food industry.

- Construction: Employed in cement-based systems for improved workability and adhesion.

- Pharmaceuticals: Used in tablet coating and as a binder in drug formulations.

Polyvinyl Alcohol as a Sustainable Packaging Material

And here we come to the most interesting part: Polyvinyl alcohol is deemed safe for food packaging by the FDA, recognized as a GRAS (Generally Recognized as Safe) ingredient.

How is Polyvinyl Alcohol Used in Packaging

Polyvinyl alcohol (PVA) is extensively utilized in the packaging industry, showcasing its versatility in offering a range of sustainable solutions:

- Water-Soluble Films:PVA is key in creating water-soluble films for individual packaging, providing an eco-friendly option.

- Coatings for Products: Used as a coating material, enhancing packaging integrity and barrier properties for various products.

- Biodegradable Packaging: Contributes to biodegradable packaging solutions, supporting environmental sustainability.

- Edible Coatings: Applied in edible coatings for fruits and vegetables, extending shelf life sustainably.

- Capsules and Pouches: Integrated into capsule and pouch production, offering dissolvable or biodegradable options.

- Hygiene Product Packaging: Suitable for packaging hygiene products, combining water solubility and biodegradability.

What Makes Polyvinyl Alcohol Sustainable

Polyvinyl alcohol is considered a sustainable packaging material for several reasons. Its eco-friendly characteristics include biodegradability, water solubility, and a lower environmental impact compared to some conventional packaging materials. The use of PVA in packaging aligns with the growing demand for sustainable and environmentally conscious practices.

- Biodegradability: PVA is known for its biodegradable nature, contributing to the reduction of plastic waste in landfills and water bodies.

- Water Solubility: The water-soluble properties of PVA facilitate the development of dissolvable packaging solutions, reducing the environmental footprint associated with traditional packaging disposal.

- Lower Environmental Impact: Life cycle assessments demonstrate that the production and disposal of PVA result in a comparatively lower environmental impact than certain non-biodegradable packaging materials.

Regulatory Landscape for Polyvinyl Alcohol in Packaging

Polyvinyl alcohol (PVA) has undergone comprehensive sub-chronic toxicity and genotoxicity studies, confirming its safety for human exposure through various daily pathways (1,2). However, it is essential to exercise caution, especially with PVA pods that may encase ingredients, such as concentrated detergents, posing potential harm if ingested or in contact with the skin. Safeguarding against these risks is crucial, particularly in households with children.

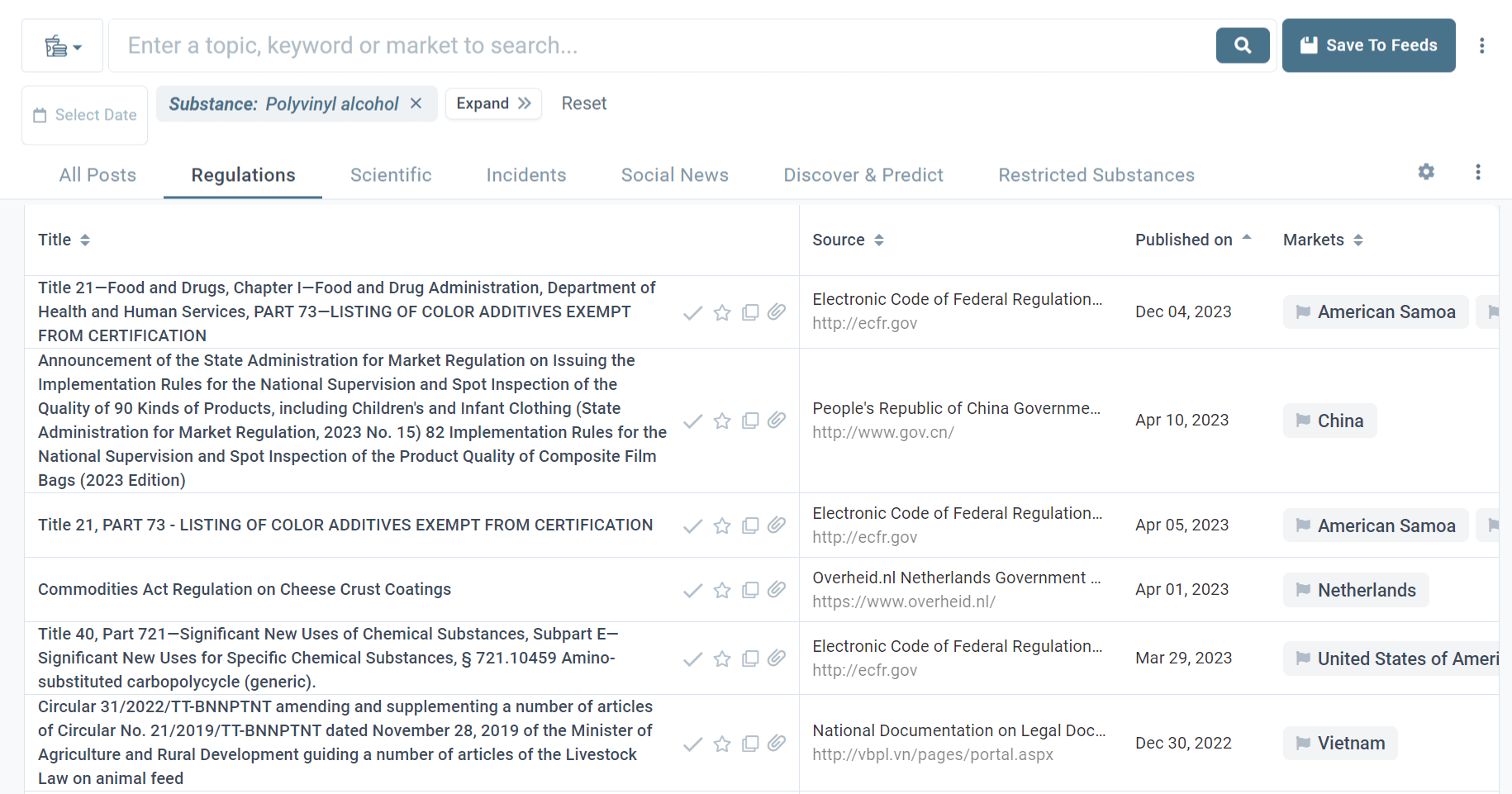

Despite the FDA and GRAS approvals attesting to its safety, a universal consensus on Polyvinyl Alcohol, particularly in the food industry, remains pending from regulatory bodies. Therefore, staying vigilant about regulatory updates is imperative. The SGS Digicomply Regulatory Intelligence Hub offers a solution by providing easy access to a comprehensive regulatory database, covering standards and requirements across 150+ jurisdictions. Leveraging advanced AI technology, it streamlines data research and retrieval, facilitating compliance initiatives and adaptation to evolving situations.

Get in touch now to learn more about the Regulatory Intelligence Hub and how it can benefit your company.

Challenges and Future Prospects of Polyvinyl Alcohol

While Polyvinyl Alcohol (PVA) shows promise for sustainable packaging, challenges include production costs and ensuring consistent quality in different environments. Ongoing research aims to optimize production, enhance material properties, and improve economic viability. Striking a balance between sustainability, performance, and cost is crucial for PVA's mainstream adoption.

The future of PVA in sustainable packaging appears promising, with ongoing innovations expected to reduce costs and enhance performance. Collaborations among research institutions, industries, and regulatory bodies can establish standardized practices, expanding PVA's versatility. As consumer preferences shift towards eco-conscious choices, Polyvinyl Alcohol is poised to play a positive and evolving role in shaping the future of sustainable packaging.

Conslusion

In concluding our exploration of Polyvinyl Alcohol (PVA), it becomes evident that this synthetic polymer holds substantial promise in steering the course of sustainable packaging. The surge in scientific attention, coupled with its recognized safety in food packaging, underscores its growing significance. Despite current challenges in production costs and consistent quality, ongoing research and collaborative efforts are poised to refine PVA's role in the industry. As consumer preferences shift towards eco-conscious choices, PVA emerges as a dynamic player in shaping the future of sustainable packaging, offering a glimpse into a greener and more environmentally responsible tomorrow.

.webp?width=1644&height=1254&name=Food%20Safety%20Dashboard%201%20(1).webp)