In the quest to curb plastic pollution, innovators are turning to mycelium – the root network of fungi – to create sustainable packaging. Mycelium packaging was already highlighted as a promising plastic alternative in previous research, but new developments are taking it even further. Imagine if packaging not only biodegraded quickly but was also edible – safe to eat or compost.

Previously, we explored how mycelium-based packaging is revolutionizing sustainability by offering a biodegradable alternative to plastics. In our article "Utilizing Mycelium to Replace Plastics for Sustainable Packaging", we discussed its potential to replace traditional packaging materials, its environmental benefits, and its growing adoption across industries.

This article explores recent scientific breakthroughs in mycelium-based edible packaging, real-world commercial adoption, regulatory considerations for edible use, comparisons with other edible packaging solutions, and future industry trends. We build on earlier insights without repeating them, diving into what’s new and exciting in this fungi-fueled packaging revolution.

Scientific Breakthroughs in Mycelium Packaging Technology

What’s new in mycelium packaging research? Scientists have been busy enhancing mycelium materials for better performance and new uses. One breakthrough came from researchers in Japan who found a way to extract “mycelial pulp” – fine mycelium fibers – from mushroom fruiting bodies without damaging their structure. By using sunlight to bleach the fibers and gentle ultrasonic treatment, they produced a clean, white mycelium pulp suitable for making packaging and leather-like materials. This means mycelium can be processed more like traditional paper or textile fibers, opening doors to thinner, flexible packaging formats.

Another innovation involves reinforcing mycelium with natural fibers to improve its properties. A 2024 study combined oyster mushroom mycelium grown on spent coffee grounds with pineapple leaf fibers, creating a composite that’s stronger and more water-resistant. By adjusting the fiber content, the researchers could boost the material’s durability and even its resistance to moisture – a key challenge for any edible or biodegradable packaging. These scientific advances address earlier limitations (like brittleness or sensitivity to water) and expand where mycelium packaging can be applied.

Engineers in Europe have also developed new production techniques for mycelium materials. In Germany, Fraunhofer Institute scientists introduced a continuous roll-to-roll cultivation process to mass-produce mycelium sheets with consistent quality. Traditionally, mycelium goods were grown in molds or trays, which made scaling up slow. The roll-to-roll method allows mycelium to be grown in a controlled, continuous layer – much like fabric – which can then be cut or formed as needed. This innovation not only improves scalability but also consistency, ensuring each batch of material has uniform strength and safety. Such a process could potentially produce wafer-thin mycelium films or coatings, moving beyond the foam-like blocks of early mycelium packaging into thinner wraps or liners. Researchers are even exploring AI optimization of growth conditions and substrates to fine-tune material properties, meaning future mycelium packaging could be tailor-made to be extra flexible, stronger, or more impermeable as required.

These breakthroughs in material science and engineering are accelerating mycelium packaging’s viability. The improved fibers, composites, and production methods directly contribute to making mycelium-based packaging suitable for more demanding uses – including edible packaging that can safely contact food or even be ingested. The science is clear that mycelium is more than just “mushroom foam” now; it’s a tunable biomaterial platform.

Commercial Applications and Industry Adoption Trends

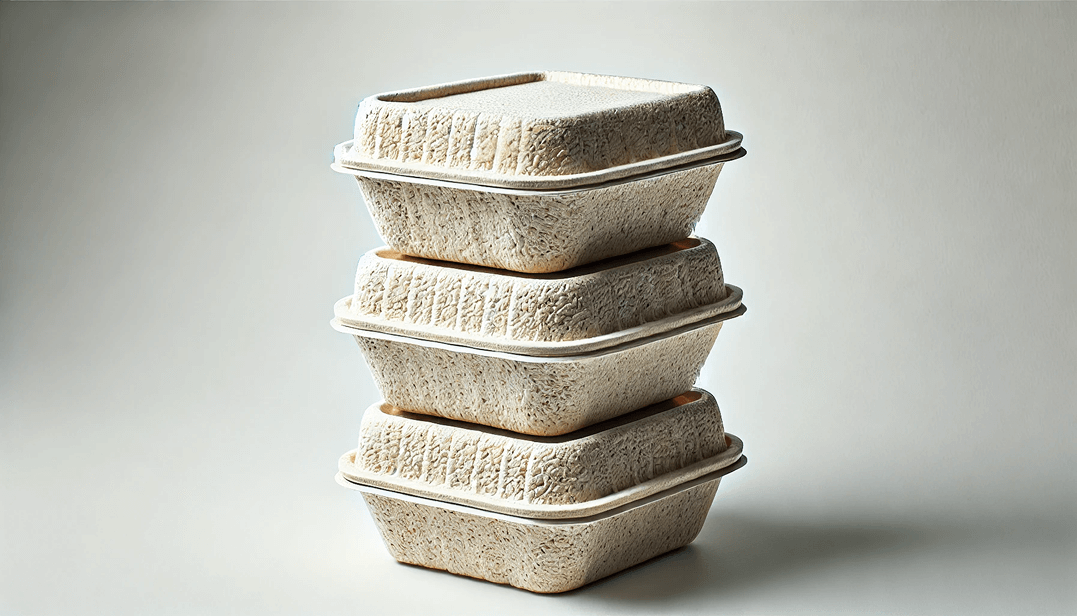

Mycelium packaging is no longer an academic idea – it’s being rolled out in real products and attracting major investment. Big-name companies are testing and adopting mycelium-based packaging for its eco-friendly appeal. For example, Dell has used mycelium foam inserts to ship laptops, replacing styrofoam cushioning. IKEA has invested in mushroom packaging development to eliminate plastic foam in its furniture packages, and even Adidas has experimented with mycelium for shoe packaging. These early adopters show confidence that mycelium can protect products in transit while meeting consumers’ sustainability expectations. Notably, Adidas’ use of mycelium packaging for shoes reinforces that even weight-sensitive industries (like apparel) find the material sufficiently lightweight and strong.

Start-ups and packaging suppliers are scaling up production to meet growing demand. US-based Ecovative Design pioneered mycelium packaging and licensed its technology globally. In the UK, the Magical Mushroom Company (MMC) set up facilities to grow mycelium packaging for clients ranging from cosmetics brands to furniture makers. They combine fungal mycelium with hemp or wood waste to create custom-molded packaging that’s home compostable and even safe if accidentally consumed by wildlife. The main component of mycelium, chitin, naturally breaks down and even has antimicrobial properties, which adds value in food packaging contexts. Today, you can find everything from mycelium wine shippers to electronics padding and even thermal coolers made of mycelium foam.

Industry trends point to rapid growth in this sector. Market analyses project the global mushroom packaging market will roughly double over the next decade, from about $68 million in 2024 to $142 million by 2034. Drivers include not only eco-conscious startups but also regulatory pushes (bans on single-use plastics, requirements for compostable materials) and the cost advantages as production scales. While currently mycelium packaging can be a bit pricier than mass-produced plastic, companies are finding that in larger quantities it becomes cost-competitive. In fact, some brands see a marketing advantage: packaging that literally grows from mushrooms is a compelling story for consumers seeking sustainable products.

Real-world examples highlight the versatility of commercial mycelium packaging. High-end spirit brands have used molded mycelium to cradle bottles in elegant, waste-free gift boxes. Furniture companies replace bulky foam corners with mycelium blocks that can be tossed into the garden to biodegrade. Perhaps most relevant to “edible” packaging, some food producers are looking at mycelium for shipping containers that might come into direct contact with food – for instance, farms using mycelium trays to protect produce. Because it’s organic and non-toxic, there’s no worry if a few mycelium particles end up on the food (unlike styrofoam bits). The trend is clear: as technical challenges are solved, industry adoption of mycelium packaging is accelerating across sectors, from tech to textiles to food and beverage.

Regulatory Considerations for Edible Mycelium Packaging

Is it safe (and legal) to eat packaging made from mycelium? If produced correctly, mycelium-based packaging can be safe to ingest, but there are important regulatory factors to consider. Edible packaging blurs the line between a food product and a packaging material in the eyes of regulators. Companies venturing into edible mycelium packaging must ensure two levels of safety: food contact safety and food consumption safety.

Food Contact: Mycelium packaging intended to wrap or hold food must comply with food contact material regulations. In the U.S., the FDA’s Title 21 CFR sets out standards to ensure that any material touching food does not leach harmful substances. Mycelium-based materials can meet these requirements by using only food-safe inputs (e.g. clean agricultural waste, edible fungal strains) and by testing for chemical migration. In fact, there are already explicit FDA guidelines acknowledging mycelium as a safe food ingredient when grown on acceptable substrates. The FDA considers mushroom mycelium suitable for food use, but requires that it be clearly labeled as mycelium (not misleadingly called “mushroom”) if eaten. This means if a company makes a soup packet out of mycelium or an edible mycelium cup, the labeling should indicate fungal mycelium content, just as one would identify other ingredients.

In the EU, materials used for food packaging must adhere to Regulation (EU) No. 10/2011, which involves rigorous testing to ensure no unsafe migration of components from the packaging into the food. Mycelium packaging would need to be tested for things like heavy metals and toxins, much like any plastic alternative. Fortunately, mycelium grown on clean plant-based substrates tends to have low levels of contaminants. Certifications for compostability (EN 13432 in Europe, ASTM D6400 in the U.S.) also include checks that the material leaves no toxic residue as it breaks down – an important consideration if the packaging is meant to biodegrade in the environment or be composted along with food waste.

Food Consumption: If the intent is for the packaging itself to be eaten (not just to be safe if accidentally consumed), then it might be regulated as a food product or food additive. In practice, most “edible” packaging today is optional to eat – for example, you can swallow an edible wrapper or simply dispose of it without harm. Mycelium-based edible packaging would likely follow the model of existing edible films or containers. The specific fungal species used would matter: only certain fungi are edible. Using species like oyster mushroom or yeast (whose mycelium or cells are commonly eaten) could smooth regulatory approval, whereas a wild unknown fungus might be treated as a novel food. Novel food regulations (in the EU) or FDA food additive rules could require additional safety data if the mycelium hasn’t been commonly consumed before. Companies might need to demonstrate nutritional safety (e.g. no harmful levels of intrinsic compounds) and allergenicity (some people have mushroom allergies). It’s worth noting that mycelium from well-known edible fungi is already consumed in other forms – for instance, mycoprotein products like Quorn™ are fungal mycelium grown in fermentation, approved and sold as food.

Another regulatory angle is labeling and consumer information. As mentioned, U.S. guidelines insist that foods containing mycelium clearly state it on the label. If a burger came wrapped in a mycelium-based edible film, the restaurant or manufacturer would likely need to inform the consumer, both for transparency and in case of allergies. Regulatory agencies might also look at claims – calling the packaging “edible” or “compostable” has to be truthful. In some jurisdictions, to label a product compostable, it must pass specific composting standards (like EN 13432) to ensure it breaks down within a set time without toxic remnants.

In summary, regulators are supportive of innovative sustainable packaging but will enforce safety through existing food contact and food safety rules. Companies are navigating this by using known edible fungi, obtaining food-grade certifications, and educating consumers. As edible packaging becomes more popular, we may see clearer guidelines emerge specifically for these dual-purpose materials. For now, edible mycelium packaging needs to hit the same safety benchmarks as food in order to be served on our plates – or as our plates!

Comparing Mycelium Packaging to Other Edible Packaging Solutions

Mycelium-based edible packaging is part of a broader movement to make packaging that leaves behind no waste – because you can eat or compost it. How does it stack up against other innovative edible packaging solutions currently making waves.

Runners in the 2019 London Marathon received edible water pods made of seaweed-based film instead of plastic cups, a real-world test of edible packaging in action.

One of the most celebrated examples of edible packaging is the seaweed-based pods developed by Notpla (formerly Skipping Rocks Lab). These capsules, often referred to as Ooho! bubbles, can hold water or sports drinks. They gained fame when thousands of runners in the London Marathon were handed bites of water – a blob you pop in your mouth to drink, then swallow or discard the membrane. The membrane is made from brown seaweed extract; it’s tasteless, 100% biodegradable in weeks, and of course edible. Compared to mycelium packaging, seaweed films have the advantage of being thin and flexible, suitable for liquids or sachets. Mycelium, on the other hand, has mostly been used for rigid or foam packaging. However, new techniques (like the mycelial pulp and roll-to-roll sheets) might allow mycelium to form thinner film-like packaging in the future. Seaweed packaging is great for single-use pouches and coatings (even condiment packets), whereas mycelium excels in structural packaging – think of padding, trays, or containers that need a bit of rigidity. Both are natural and compostable, but edibility differs: seaweed wraps are designed to be neutral in flavor and easy to eat; mycelium packaging might be technically edible but not as palatable (it might taste earthy or chewy unless formulated as a food).

Another emerging solution is edible tableware made from grain by-products. For instance, Polish company Biotrem produces plates and bowls pressed from wheat bran – literally dishes you can eat or compost after your meal. These wheat bran plates are sturdy enough to hold hot food, impart a mild nutty taste if you bite them, and biodegrade in about 30 days if thrown away. Compared to mycelium packaging, wheat bran products address a different need: replacing disposable plates, cups, and cutlery. They are truly edible and even nutritious (rich in fiber). Mycelium could potentially be made into edible bowls or cups, but current mycelium packaging is more focused on protective functions than serving as dinnerware. One advantage of mycelium is that it can be grown into complex shapes (like custom packaging inserts) which bran or other edible materials can’t easily replicate without molds and binders. So, a wheat bran plate can replace a paper plate, but to replace a foam packing insert around a gadget, mycelium is far better suited.

Starch-based packaging also offers edible or at least safe-to-eat options. Corn starch packing peanuts used in shipping boxes are a classic example. These puffy peanuts look like the polystyrene ones but dissolve in water and are non-toxic – there’s no harm if a child or pet (or curious adult) accidentally eats a few. While not designed as a snack, it’s reassuring that they won’t cause injury or linger in an animal’s stomach. Mycelium foam could play a similar role in the future: if used as loose fill or inserts, it would likewise be safe if ingested by wildlife or humans, since it’s just fungus and plant matter. Starch peanuts are cheap and readily available, but they can be flimsy and unsuitable for heavy items (they can compress). Mycelium packaging can be made denser and more resilient, so it might protect heavy products better while still being compostable and non-toxic. However, pure starch items are quicker to dissolve – you can literally watch a starch peanut vanish under running water – whereas a mycelium block, though biodegradable, takes a few weeks to break down in compost rather than instantly in water.

There are also protein-based films (like milk protein casein wraps or gelatin films) and polysaccharide films (from tapioca, rice, or potato) being developed as edible packaging for foods. These often serve as coatings to extend shelf life (e.g., an edible film around fruits or candies). Mycelium isn’t typically used that way; you wouldn’t wrap a cucumber in a mycelium coating, but you might pack a cucumber in a mycelium tray. The use-cases differ: mycelium shines where you need a replacement for foam, cardboard, or molded plastic, whereas films and coatings tackle the plastic wrap and plastic film problems.

In summary, mycelium-based edible packaging complements, rather than directly competes with, other edible packaging innovations. Seaweed capsules address liquids and sachets, edible plates replace single-use serveware, starch peanuts fill up shipping boxes – and mycelium can replace foam padding, insulating containers, and possibly form edible containers. An ideal future might see a combination: for example, a food delivery could come in a mycelium container with a seaweed-based transparent lid, with wheat bran cutlery – all of it edible or compostable. Each solution has its strengths, and together they point to a future with nearly zero-waste packaging.

Insights, Trends, and Future Perspectives

The rapid advancements in mycelium packaging technology and its growing adoption signal several key trends and future perspectives:

-

Convergence of Sustainability and Performance: Early on, eco-friendly packaging often meant compromising on performance or cost. That gap is closing. Mycelium packaging today offers protective qualities comparable to plastics (cushioning, insulation, even fire resistance, and ongoing R&D continues to improve these traits. The fact that you can now engineer mycelium material properties by choosing different fungi, substrates, or additives (like pineapple fiber) means future packaging can be customized per industry needs. We may soon see mycelium packaging that is water-resistant enough for refrigerated foods or even edible bottles with a mycelium-based outer shell for strength.

-

Regulatory Tailwinds: Governments worldwide are introducing stricter rules on single-use plastics and packaging waste. This is creating a tailwind for mycelium packaging. For example, extended producer responsibility laws and the proposed EU Packaging and Packaging Waste Regulation (PPWR) will push companies to use recyclable or compostable packaging. Those using mycelium or other compostables could avoid fines or taxes aimed at polluting materials. In other words, mycelium packaging is being seen as a “future-proof” solution, one that will meet upcoming regulations with ease. This regulatory support reduces the risk for businesses to switch to mycelium – and in some cases there may even be incentives or subsidies for doing so (such as government grants for circular economy initiatives).

-

Scaling Up and Cost Reduction: Investment is flowing into scaling mycelium manufacturing. New production methods like the continuous sheet growth and automated inoculation are turning what used to be a craft process into an industrial one. As facilities expand, the cost per unit is expected to drop. Analysts predict that in high volumes, mycelium packaging can reach price parity with traditional packaging, especially when you factor in the savings from not having to pay plastic waste fees or from gaining eco-conscious customers. Startups are forming partnerships with agricultural industries to secure cheap feedstock (e.g., using local farm waste to grow mycelium). There’s even exploration into 3D-printing mycelium composites, or shipping dehydrated mycelium kits to be “grown on site” for large items, which could revolutionize distribution.

-

Edible Packaging Niche Expansion: Right now, edible mycelium packaging is in its infancy, but the concept aligns with a zero-waste ethos that is very appealing. We might see inventive new products such as mycelium-based food containers that double as animal feed after use, or as compost booster. For example, a fast-food chain could serve burgers in a mycelium box that you could break up and sprinkle in your garden (or nibble on if you’re adventurous). There’s talk in sustainability circles about packaging that can nourish soil or animals instead of polluting oceans. Mycelium, being a natural biomass, fits well here – it could even be seeded with spores or nutrients so that when composted it helps other plants or fungi grow. This is a radically different mindset from conventional packaging, turning a waste product into a beneficial resource.

-

Consumer Perception and Education: As these solutions emerge, consumer acceptance is crucial. Thankfully, people are warming up to the idea. The marathon example of edible water pods was met with curiosity and generally positive feedback – runners found it novel and eco-friendly. Similarly, when given a mycelium packaging piece, consumers often marvel at the fact it’s made from mushrooms. It invites engagement: some might ask “Can I really eat this?” which is a great opportunity to discuss sustainability (even if the answer is “you could, it’s safe, but it might not taste great!”). Companies adopting edible or mushroom packaging are using clever branding to highlight these features, sometimes even printing instructions like “Don’t trash me – plant me!” on the packaging. The trend is that sustainability sells, and telling the story of packaging made from fungi or seaweed can enhance a brand’s image. In the near future, we may see labels such as “Produced with 100% edible packaging – no waste left behind!” as a selling point.

Looking ahead, the future of mycelium-based edible packaging appears bright. It sits at the intersection of cutting-edge material science and a global drive toward sustainability. Challenges remain – like improving water resistance for all applications, securing regulatory approvals for edible uses, and scaling production further – but the momentum is undeniable. In a few years, it might be commonplace to receive packages or take-out food in containers that are completely compostable or edible. The progress in mycelium technology is a prime example of how a nature-inspired solution can transform an industry: what started as fungi growing in a lab is now growing into a multi-million-dollar effort to reinvent packaging.

Conclusion

Mycelium-based edible packaging exemplifies innovation for a circular economy – leveraging fungi’s natural abilities to create packaging that nurtures rather than harms the planet. Recent scientific breakthroughs have enhanced mycelium materials’ strength, scalability, and safety, bringing the idea of edible, compostable packaging closer to reality. Companies across industries are beginning to swap out plastics and foams for mycelium, driven by both consumer demand and impending regulations that favor sustainable alternatives. While mycelium packaging has unique advantages in its biodegradability and versatility, it is part of a broader ecosystem of edible packaging solutions each suited to different needs. Together, these solutions hint at a future where packaging waste could virtually be eliminated.

In that future, you might unbox a product and then decide to compost the packaging – or perhaps even take a bite of it! That prospect may raise an eyebrow today, but it prompts an important question: Should our packaging be something we could safely eat? If the answer is “why not,” then mycelium is well on its way to making it possible. By building on fungi technology, industry know-how, and smart regulations, mycelium-based edible packaging is not just a fanciful idea but an emerging reality. It invites us to rethink what packaging can be – from a pollutant to a product that’s truly part of nature’s cycle. The advancements discussed here show an exciting path forward, one where our packaging might one day be as nourishing to the Earth as the products it contains are to us.

Sources:

- Shinshu University – Extraction of white mycelial pulp for sustainable packaging

- Fraunhofer IAP – Continuous production of mycelium materials for packaging

- BIOTEC/NSTDA (Thailand) – Mycelium composites with coffee and pineapple fiber

- SGS Digicomply – Mycelium packaging applications and industry uptake

- Grown.Bio – Sustainable packaging regulations and mycelium (blog)

- Blogpackers – Regulatory standards for mycelium food contact and safety

- FDA CPG 585.525 – Guidance on mushroom mycelium use in food

- Runner’s World – Seaweed-based edible water pods at London Marathon

- MaterialDistrict – Edible wheat bran plates by Biotrem

- Route Blog – Starch-based packing peanuts are non-toxic and dissolvable

.webp?width=1644&height=1254&name=Food%20Safety%20Dashboard%201%20(1).webp)