Baby food recalls are a critical aspect of food safety due to the unique vulnerability of infants and young children. When a safety issue arises in baby food products, the consequences can be severe, affecting not only the health of infants but also the trust that parents place in brands. This guide delves into the nuances of baby food recalls, examining the causes, regulatory responsibilities, and impact on manufacturers, along with strategies for prevention. By understanding these facets, industry professionals can better protect their brands, comply with regulations, and ensure the highest standards of safety for their youngest consumers. Let's dive into this type of Food Recall

What is a Baby Food Recall?

A baby food recall is an urgent action taken to remove potentially harmful products from distribution, sale, or consumption. Recalls can be initiated voluntarily by manufacturers or mandated by regulatory bodies such as the U.S. Food and Drug Administration (FDA) or the European Food Safety Authority (EFSA). Given the delicate health and developing immune systems of infants, even minor issues can trigger significant health risks, making recalls a crucial tool for immediate intervention. Baby food recalls may involve a variety of products, including purees, infant cereals, snacks, and liquid or powdered formulas. The process is designed to minimize exposure and mitigate potential harm by rapidly informing and removing affected products from the market.

Main Causes and Hazards of Baby Food Recalls

The reasons for baby food recalls are diverse, but they often revolve around contaminants, nutritional imbalances, and labeling errors. Here’s a closer look at some of the most common causes:

-

Heavy Metal Contamination: One of the most concerning issues, heavy metals like lead, arsenic, mercury, and cadmium can enter baby food through contaminated soil or water sources where ingredients are grown. Prolonged exposure to these toxins, even in small amounts, can negatively impact cognitive development and pose long-term health risks for infants.

-

Microbial Contamination: Pathogens such as Salmonella, Listeria monocytogenes, and Cronobacter sakazakii are particularly dangerous in baby food, as they can cause severe infections in infants. These bacteria may be introduced during processing, storage, or through contamination of raw ingredients, making strict sanitation protocols essential.

-

Nutritional Imbalance: Baby food must meet precise nutritional standards to support healthy growth and development. Products may be recalled if they have nutrient deficiencies or excesses. For instance, an overdose of vitamin D can lead to kidney issues, while insufficient iron can hinder cognitive development. Ensuring proper nutritional content is vital for products marketed specifically for infants.

-

Foreign Objects: Physical contaminants such as plastic, glass, or metal fragments can occasionally end up in baby food during production. These objects pose serious risks, including choking and internal injuries, making this one of the more visible and urgent causes for recall.

-

Allergen Mislabeling: Accurate labeling is crucial, especially in products meant for young children who may have severe allergies. Mislabeling ingredients like dairy, soy, or nuts can result in life-threatening allergic reactions. Proper allergen management and label verification are essential to avoid such recalls.

Each of these hazards underscores the importance of robust quality control throughout the production process. Manufacturers must monitor their supply chains, enforce strict sanitation measures, and ensure accurate labeling to minimize the risk of these issues.

Regulatory Authorities' Rights and Responsibilities in Baby Food Recalls

Regulatory bodies like the FDA play an essential role in ensuring that baby food recalls are managed effectively. These agencies have a range of responsibilities and powers to protect public health, particularly when it involves vulnerable populations like infants.

Regulatory authorities begin by assessing the severity of the issue. For example, the FDA may classify a recall as Class I (high risk) if the product could cause severe harm, while Class III recalls involve minor labeling issues without immediate health risks. This classification system helps prioritize actions and resources.

Regulatory agencies are also responsible for inspecting facilities, collecting samples, and verifying hazards. When a problem is identified, they may require companies to cease production temporarily, investigate the root cause, and implement corrective actions to prevent recurrence. Additionally, if a manufacturer fails to voluntarily recall a dangerous product, regulatory bodies have the authority to mandate a recall to ensure public safety.

Beyond enforcement, regulatory authorities provide guidance on best practices for recall management and product safety. They issue public notifications, allowing parents and caregivers to quickly identify and avoid affected products. This transparent communication not only aids public safety but also fosters accountability within the industry.

Impact of Baby Food Recalls on Manufacturers

A recall can have far-reaching consequences for manufacturers, touching every facet of business from finances to brand perception:

-

Financial Costs: The direct costs of removing products, testing other batches, and implementing corrective measures can be steep. Indirectly, recalls often lead to lost sales, reduced market share, and the potential for costly legal settlements with affected families.

-

Reputation Damage: Recalls of baby food can deeply impact consumer trust, as parents are particularly sensitive to risks affecting their children. Rebuilding a damaged reputation can be challenging, requiring ongoing transparency and improved safety measures to regain customer confidence.

-

Increased Regulatory Scrutiny: After a recall, companies often face closer monitoring from regulatory bodies. This increased scrutiny may involve more frequent inspections, mandatory audits, or additional compliance requirements, all of which can strain company resources.

-

Supply Chain Disruption: Recalls disrupt the supply chain, affecting relationships with suppliers, distributors, and retailers. Companies may need to renegotiate contracts, implement stricter quality controls, and work to rebuild damaged business relationships.

These impacts highlight the importance of taking preventive measures and having a well-structured recall plan in place to manage risks swiftly and effectively.

What Happens to Recalled Products

Once a baby food recall is initiated, manufacturers are responsible for managing the affected products. This process involves careful decision-making to ensure recalled items are handled ethically and responsibly.

-

Destruction: If contamination cannot be rectified, the most common outcome for recalled products is destruction. This may involve incineration or disposal in an environmentally safe manner, ensuring the products cannot re-enter the market.

-

Reprocessing: In some cases, products can be reprocessed to remove contaminants and re-evaluated for safety. This approach requires rigorous quality control and testing to ensure the products meet safety standards before they are reintroduced to the market.

-

Alternative Use or Donation: While rare, some recalled products that don’t pose a direct health risk might be repurposed for non-infant uses or donated to organizations such as animal shelters. Regulatory approval is required to ensure safety, and this option is typically limited to specific cases.

By managing recalled products responsibly, manufacturers uphold ethical standards, maintain compliance, and help restore consumer confidence.

Preventive Measures for Baby Food Recalls

Preventing recalls is the ultimate goal for manufacturers. Implementing a proactive approach to food safety can help companies maintain consumer trust and regulatory compliance. Key preventive measures include:

-

Enhanced Quality Control: Routine testing and strict quality control processes at every production stage can detect and eliminate contaminants before products reach the market.

-

Supplier Audits: Working closely with suppliers and conducting regular audits helps ensure that raw materials meet safety standards. Establishing strict supplier criteria minimizes the risk of contamination from external sources.

-

Accurate Label Management: Ensuring that all labels are accurate and contain essential allergen information can prevent mislabeling-related recalls. Properly labeled products reduce risks and ensure that consumers have the information they need to make safe choices.

-

Compliance Audits and Risk Assessments: Regular audits, both internal and third-party, help identify potential safety risks and ensure that all processes align with regulatory requirements. These audits enable manufacturers to detect and address issues before they escalate.

-

Employee Training: Educating employees on food safety protocols and recall procedures empowers them to recognize and respond to potential hazards. Well-trained staff are a company’s first line of defense against safety issues.

By adhering to these practices, manufacturers can reduce the likelihood of recalls, thereby protecting both their brand and their youngest consumers.

Last Month's Food Recalls and Safety Incidents

Explore the latest food recalls, market withdrawals, and safety alerts in our free Food Safety Incidents Dashboard. Updated monthly and powered by SGS Digicomply, this dashboard provides a clear, filterable list of last month’s global food recalls and incidents, allowing you to stay informed on the products and hazards affecting the industry.

How manufacturers and companies can track and utilize global recall data:

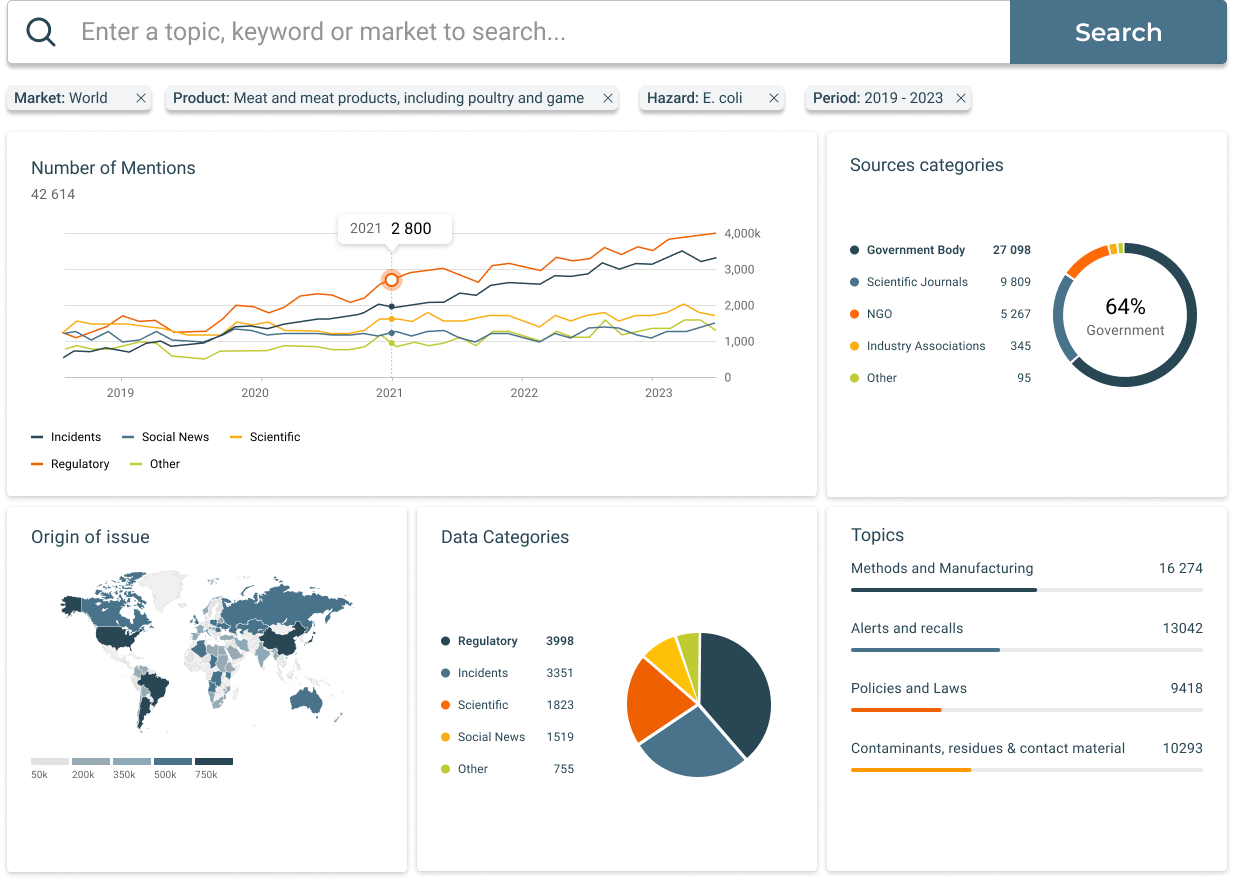

SGS Digicomply continuously monitors and analyzes millions of data sources across over 160 jurisdictions. With easy-to-use filters for sources, locations, products, substances, hazards, and more, our platform allows manufacturers to track recall trends and gain actionable insights powered by AI-Copilot.

Explore our interactive demos to see these tools in action.

By combining diverse data sources, SGS Digicomply offers the most comprehensive and targeted screening of food safety data, contextualized with real-time lab data to identify emerging risks.

.webp?width=1644&height=1254&name=Food%20Safety%20Dashboard%201%20(1).webp)