Lettuce is a staple in many households and restaurants, commonly used in salads, sandwiches, and as a garnish. However, this seemingly simple leafy green has been the subject of numerous recalls due to contamination risks. Lettuce recalls are often triggered by outbreaks of foodborne pathogens, such as E. coli and Salmonella, which can lead to serious illness in consumers. This comprehensive guide examines the causes of lettuce recalls, the recall process, regulatory roles, and preventive measures to ensure safety in the supply chain from farm to table. Let's dive into this type of Food Recall.

What is a Lettuce Recall?

A lettuce recall is the process of removing contaminated or otherwise unsafe lettuce products from distribution, sale, or consumption. Recalls may be initiated by lettuce producers, retailers, or mandated by regulatory agencies such as the FDA in the U.S. and EFSA in Europe. The goal is to protect public health by swiftly removing potentially dangerous products from the supply chain, preventing the spread of illnesses caused by foodborne pathogens.

Lettuce recalls can impact various types of lettuce, including romaine, iceberg, butterhead, and mixed salad greens. Due to the high water content and lack of protective skin, lettuce is particularly vulnerable to contamination, which makes managing and preventing recalls a top priority for both producers and regulators.

Main Causes and Hazards of Lettuce Recalls

Lettuce recalls are often the result of contamination, and certain environmental and handling factors increase the risk. Here are the most common causes of lettuce recalls:

-

Microbial Contamination: Pathogens like E. coli, Salmonella, and Listeria are among the leading causes of lettuce recalls. These bacteria can enter the supply chain at various stages, from contaminated soil and water during cultivation to improper handling during processing. Outbreaks linked to contaminated lettuce can lead to severe gastrointestinal illnesses and, in extreme cases, hospitalization.

-

Cross-Contamination in Processing: Lettuce is usually processed and packaged in facilities that handle large volumes of produce. If equipment or surfaces are not sanitized properly, pathogens can transfer from one batch to another, increasing the spread of contamination.

-

Environmental Contamination: Lettuce fields may be exposed to contaminated water sources, such as nearby rivers or runoff from livestock farms. Waterborne pathogens can easily transfer to lettuce plants, especially when overhead irrigation is used.

-

Improper Refrigeration: Lettuce requires proper storage temperatures to maintain freshness and prevent the growth of harmful bacteria. When lettuce is improperly refrigerated during transportation or at retail points, it can become a breeding ground for pathogens.

Each of these causes poses a significant risk to consumer health, making it essential for producers and suppliers to adopt rigorous quality control and sanitation practices to reduce the likelihood of recalls.

Regulatory Authorities' Role in Lettuce Recalls

Regulatory bodies such as the FDA and CDC in the United States play a pivotal role in managing lettuce recalls. Their responsibilities include:

-

Monitoring and Surveillance: The FDA and CDC continuously monitor reported cases of foodborne illnesses. When an outbreak is linked to lettuce, these agencies investigate the source to identify and contain the risk.

-

Enforcement of Safety Standards: Regulations under the Food Safety Modernization Act (FSMA) require lettuce producers to follow strict guidelines for sanitation and testing. If these standards are not met, the FDA has the authority to mandate recalls or halt production.

-

Traceability and Rapid Response: Regulatory authorities work with producers to ensure that lettuce is traceable from farm to retail. This traceability allows agencies to quickly identify and remove contaminated products from the supply chain, minimizing the spread of illness.

-

Public Communication and Alerts: When a lettuce recall occurs, regulatory bodies issue public warnings through media outlets and official websites. This communication is vital for informing consumers and retailers about the risks and providing guidance on handling or disposing of affected products.

These efforts ensure that lettuce recalls are managed effectively, protecting public health and maintaining consumer confidence in the food supply.

Impact of Lettuce Recalls on the Industry

Lettuce recalls can have a profound impact on the entire supply chain, affecting farmers, processors, distributors, and retailers:

-

Financial Losses: Lettuce recalls lead to direct costs from removing products, testing, and sanitation. Farmers may face financial hardship, especially if they must halt production or destroy crops.

-

Damage to Brand Reputation: Companies involved in lettuce recalls may suffer from negative publicity, leading to a loss of consumer trust. Rebuilding reputation requires time, transparency, and a demonstrated commitment to safety.

-

Stricter Regulatory Oversight: After a recall, regulatory agencies often increase scrutiny of involved parties, leading to more frequent inspections and, in some cases, additional regulatory requirements.

-

Supply Chain Disruption: Lettuce recalls disrupt the supply chain, impacting everyone from farm workers to logistics providers. Companies may need to adjust contracts, work closely with suppliers, and implement stricter quality control measures to restore normal operations.

Understanding these impacts is crucial for industry players, as it highlights the importance of implementing preventive measures and preparing for effective recall management.

Preventive Measures for Lettuce Recalls

Reducing the likelihood of lettuce recalls requires a proactive approach to safety and quality control. Key preventive measures include:

-

Strict Sanitation Protocols: Adhering to rigorous cleaning and sanitation protocols in fields, processing facilities, and transport vehicles minimizes the risk of cross-contamination and ensures that lettuce is handled safely throughout the supply chain.

-

Water Quality Testing: Regular testing of water sources used for irrigation is essential for detecting potential contaminants early. By identifying and addressing risks in water quality, growers can reduce the likelihood of microbial contamination.

-

Supplier Audits and Quality Assurance: Working with trusted suppliers and conducting regular audits helps ensure that every stage of the supply chain meets quality and safety standards. This is particularly important when sourcing raw materials from multiple locations.

-

Cold Chain Management: Maintaining proper refrigeration during storage and transportation is crucial for preserving lettuce quality and preventing bacterial growth. Companies should implement robust cold chain management practices to ensure temperature consistency.

-

Employee Training: Educating workers on food safety best practices, including proper handling, sanitation, and packaging procedures, reduces the chances of contamination at multiple points in the supply chain.

These preventive steps help protect consumer health, reduce financial risks, and maintain trust in lettuce products by minimizing the likelihood of recalls.

Conclusion

Lettuce recalls are a crucial component of food safety, especially given the susceptibility of leafy greens to contamination. By understanding the primary causes of recalls, regulatory roles, and industry impacts, companies involved in the lettuce supply chain can improve their recall management processes. Preventive measures—such as stringent sanitation, water testing, and employee training—are essential for reducing risks and ensuring that safe, high-quality lettuce reaches consumers.

For companies, the key to successful lettuce recall management lies in proactive preparation and a commitment to transparency. By adhering to food safety standards and working closely with regulatory authorities, lettuce producers and suppliers can protect their brands and contribute to a safer food supply for everyone.

Last Month's Food Recalls and Safety Incidents

Explore the latest food recalls, market withdrawals, and safety alerts in our free Food Safety Incidents Dashboard. Updated monthly and powered by SGS Digicomply, this dashboard provides a clear, filterable list of last month’s global food recalls and incidents, allowing you to stay informed on the products and hazards affecting the industry.

How manufacturers and companies can track and utilize global recall data:

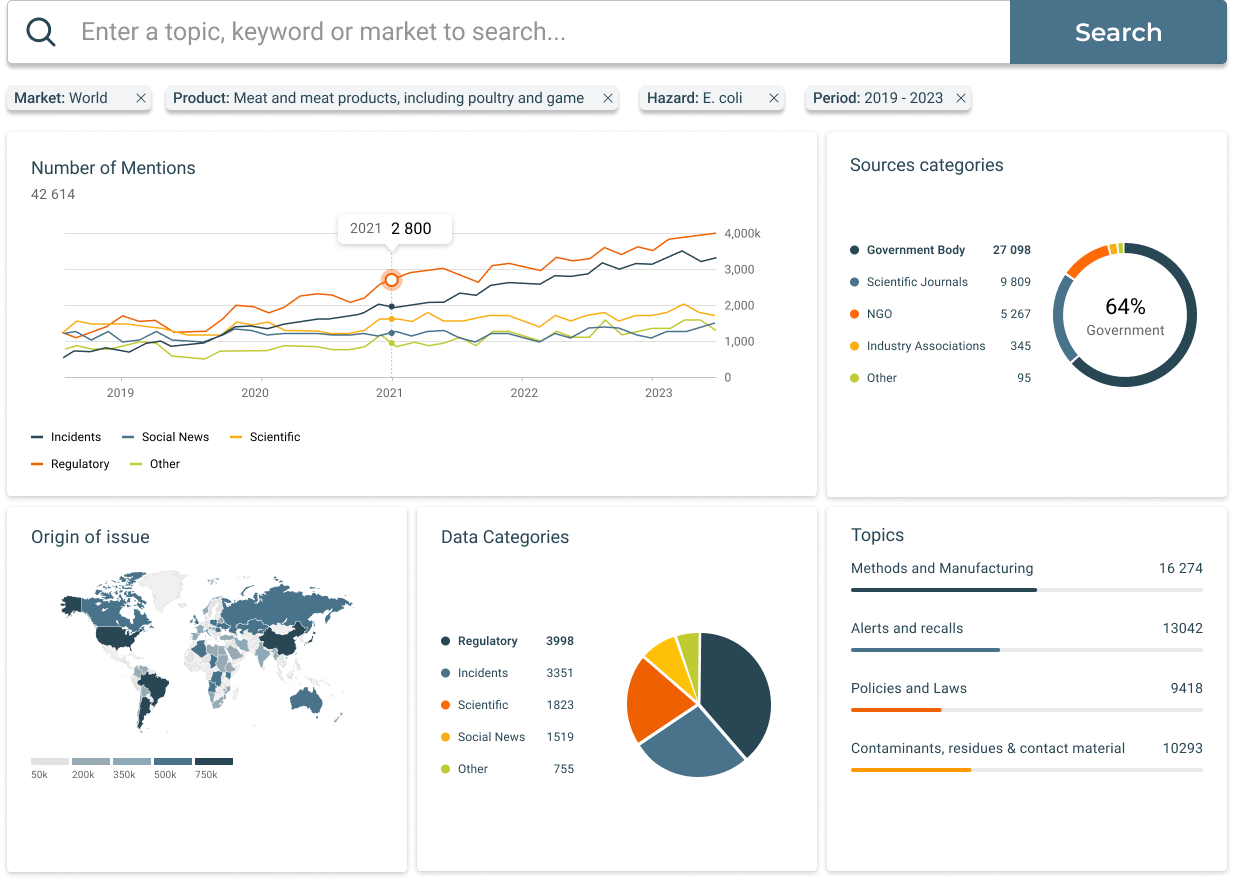

SGS Digicomply continuously monitors and analyzes millions of data sources across over 160 jurisdictions. With easy-to-use filters for sources, locations, products, substances, hazards, and more, our platform allows manufacturers to track recall trends and gain actionable insights powered by AI-Copilot.

Explore our interactive demos to see these tools in action.

By combining diverse data sources, SGS Digicomply offers the most comprehensive and targeted screening of food safety data, contextualized with real-time lab data to identify emerging risks.

.webp?width=1644&height=1254&name=Food%20Safety%20Dashboard%201%20(1).webp)