Strawberries are a beloved fruit, enjoyed fresh or in products like smoothies, jams, and desserts. However, strawberry recalls have become more frequent in recent years due to contamination risks, particularly from pathogens like Hepatitis A and Listeria monocytogenes. Because strawberries are typically consumed raw, contamination can pose serious health risks to consumers. This guide explores the main causes of strawberry recalls, the role of regulatory authorities, industry impact, and preventive measures that can help maintain the safety and quality of strawberries in the supply chain. Let's dive into this type of Food Recall.

What is a Strawberry Recall?

A strawberry recall is the process of removing potentially unsafe or contaminated strawberries from the market. Recalls can be initiated voluntarily by producers or mandated by regulatory bodies such as the FDA. The goal is to protect consumers from health risks associated with contaminated strawberries, particularly those linked to foodborne pathogens.

Strawberry recalls can affect fresh, frozen, and processed products, given the range of ways strawberries are used. Because strawberries are often eaten fresh and unwashed, they are particularly vulnerable to contamination, making recall management and preventive practices critical.

Main Causes and Hazards of Strawberry Recalls

The main reasons for strawberry recalls stem from contamination and food safety hazards. Key causes include:

-

Viral Contamination (e.g., Hepatitis A): Hepatitis A is a serious viral infection that can be transmitted through contaminated food. Strawberries, if handled by infected workers or exposed to contaminated water sources, can carry the virus, which is resilient even in cold storage. Infection with Hepatitis A can lead to severe liver disease, especially in young children and older adults.

-

Bacterial Contamination (e.g., Listeria): Listeria monocytogenes is a bacterial pathogen that can survive in refrigerated environments, making it particularly problematic for strawberries stored in cool conditions. Listeria infection can lead to listeriosis, a serious illness that primarily affects pregnant women, infants, the elderly, and immunocompromised individuals.

-

Pesticide Residues: Improper pesticide use or inadequate washing can lead to excessive pesticide residues on strawberries. High levels of pesticide residue may pose health risks, especially for consumers who eat strawberries frequently or in large quantities.

-

Foreign Material Contamination: Small pieces of plastic, glass, or metal can sometimes end up in strawberries during processing or packaging. These foreign materials can cause choking hazards or internal injuries, making them a significant reason for recalls.

Each of these hazards underscores the importance of strict quality control and proper handling of strawberries to prevent contamination and ensure consumer safety.

Regulatory Authorities' Role in Strawberry Recalls

In the United States, the FDA is primarily responsible for managing strawberry recalls, while the CDC may also be involved in investigating outbreaks. Key roles of regulatory authorities in strawberry recalls include:

-

Inspection and Testing: The FDA conducts regular inspections of facilities that handle strawberries, including farms and processing plants. The agency also performs sampling and testing to identify contaminants like Hepatitis A, Listeria, and pesticide residues.

-

Recall Classification: If a recall is necessary, the FDA classifies it based on risk severity:

- Class I Recall: High risk, involving products that could cause serious health consequences or death, such as strawberries contaminated with Hepatitis A.

- Class II Recall: Moderate risk, where the product may lead to temporary health issues but is unlikely to cause severe illness.

- Class III Recall: Low risk, involving products that violate regulations but are unlikely to pose a direct health threat.

-

Public Notification: Regulatory authorities issue public notices for Class I and II recalls to inform consumers about potentially dangerous products. These notifications provide information on the affected products, lot numbers, and guidance for consumers on what to do.

-

Monitoring Recall Effectiveness: During a recall, the FDA tracks the removal of affected products and ensures that all necessary steps are taken to contain the contamination. They may require companies to submit reports documenting recall actions and to implement corrective measures.

The FDA’s involvement in strawberry recalls ensures that risks are managed effectively and transparently, safeguarding public health.

Impact of Strawberry Recalls on the Industry

Strawberry recalls can have far-reaching consequences for producers, distributors, and retailers, affecting business and public perception. Key impacts include:

-

Financial Losses: Recalls generate direct costs from retrieving products, testing batches, and addressing contamination sources. Additional costs arise from potential lost sales, reduced demand, and legal fees if consumers are affected.

-

Reputational Damage: Strawberry recalls, especially those involving serious pathogens, can erode consumer trust. Negative publicity can impact a brand’s reputation and long-term sales, requiring significant effort to rebuild public confidence.

-

Regulatory Oversight and Compliance Costs: Following a recall, companies often face heightened regulatory scrutiny, which can involve more frequent inspections, stricter compliance standards, and additional reporting requirements.

-

Supply Chain Disruption: Strawberry recalls impact the entire supply chain, from farms to retailers. Restoring normal operations requires effective coordination with suppliers and distributors to ensure safe products are available to consumers.

Understanding these impacts highlights the importance of proactive safety measures to reduce the risks of strawberry recalls and maintain stable supply chain operations.

Preventive Measures for Strawberry Recalls

Preventing strawberry recalls requires a commitment to food safety at every stage of production. Key preventive measures include:

-

Good Agricultural Practices (GAPs): Implementing GAPs ensures that strawberries are grown, harvested, and handled in ways that minimize contamination risks. This includes using safe water sources, proper sanitation, and training farm workers on food safety.

-

Sanitation and Hygiene Protocols: Regular sanitation and hygiene practices in facilities that handle strawberries help prevent contamination from microbial pathogens. Cleaning equipment, surfaces, and packaging areas is essential to reduce contamination risks.

-

Pesticide Management and Testing: Proper use of pesticides, as well as regular testing for residues, helps ensure that strawberries meet safety standards. This protects consumers and aligns with regulatory guidelines on acceptable pesticide levels.

-

Water Quality Testing: Testing water used for irrigation and washing strawberries is essential for detecting potential contaminants. Using clean water sources reduces the risk of microbial contamination and ensures safe produce.

-

Cold Chain Management: Maintaining proper refrigeration from harvest to retail preserves strawberry quality and helps inhibit the growth of harmful pathogens like Listeria. Effective cold chain management ensures that strawberries remain fresh and safe for consumers.

-

Employee Training and Safety Protocols: Educating employees on food safety practices, such as proper hand hygiene and contamination prevention, reduces human error and enhances safety throughout the supply chain.

By incorporating these preventive measures, strawberry producers and processors can minimize the risk of recalls and ensure that high-quality, safe products reach consumers.

Conclusion

Strawberry recalls are an essential component of food safety, especially given the susceptibility of fresh produce to contamination. Understanding the primary causes of recalls—such as microbial hazards and pesticide residues—enables companies to implement proactive safety measures, comply with regulatory requirements, and reduce the risk of recalls.

For industry professionals, the key to successful strawberry recall management is prevention. Adopting good agricultural practices, ensuring thorough sanitation, and maintaining proper cold chain practices help protect consumer health and uphold product quality. By working closely with regulatory bodies like the FDA, strawberry producers can enhance their recall management processes, build consumer confidence, and contribute to a safer food supply.

Last Month's Food Recalls and Safety Incidents

Explore the latest food recalls, market withdrawals, and safety alerts in our free Food Safety Incidents Dashboard. Updated monthly and powered by SGS Digicomply, this dashboard provides a clear, filterable list of last month’s global food recalls and incidents, allowing you to stay informed on the products and hazards affecting the industry.

How manufacturers and companies can track and utilize global recall data:

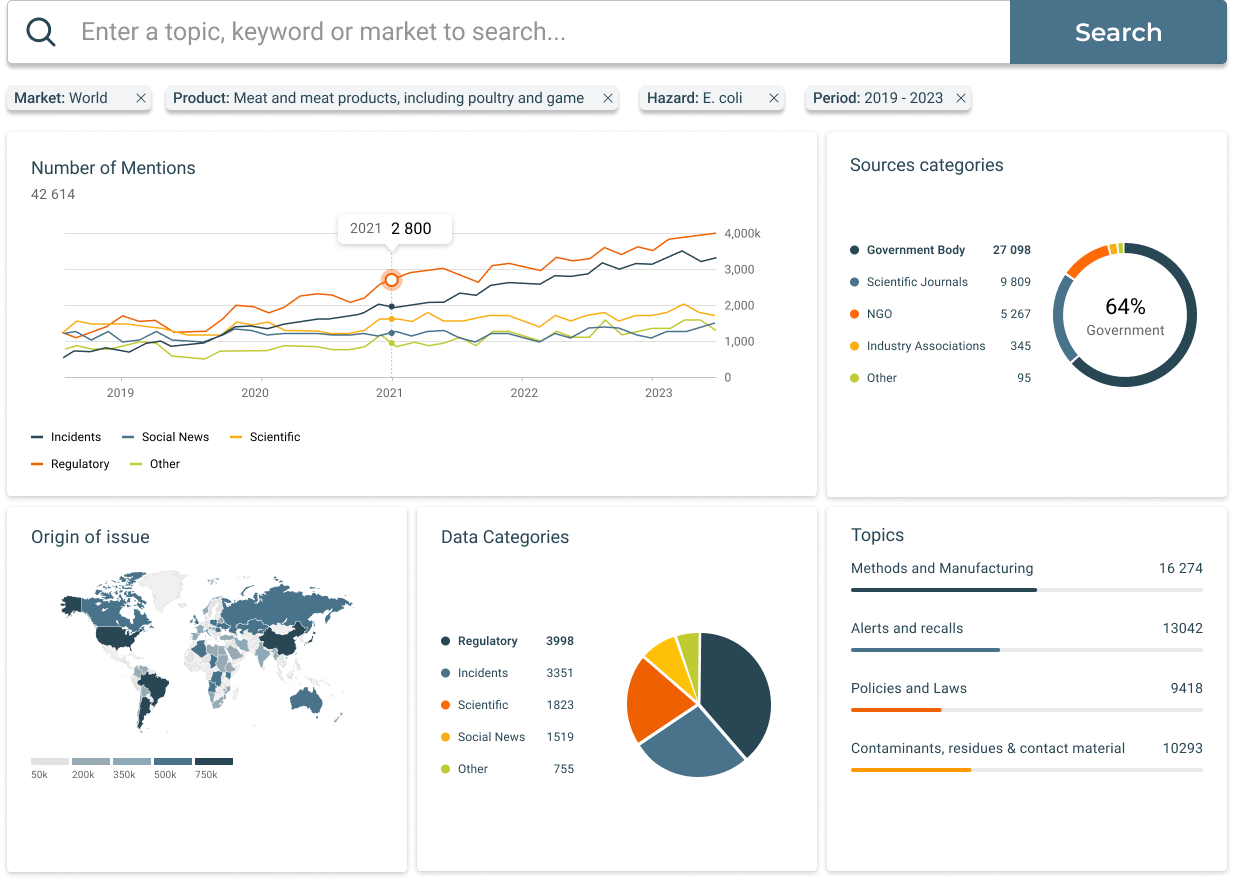

SGS Digicomply continuously monitors and analyzes millions of data sources across over 160 jurisdictions. With easy-to-use filters for sources, locations, products, substances, hazards, and more, our platform allows manufacturers to track recall trends and gain actionable insights powered by AI-Copilot.

Explore our interactive demos to see these tools in action.

By combining diverse data sources, SGS Digicomply offers the most comprehensive and targeted screening of food safety data, contextualized with real-time lab data to identify emerging risks.

.webp?width=1644&height=1254&name=Food%20Safety%20Dashboard%201%20(1).webp)