This becomes a myriad of challenges to accomplish product safety, regulatory compliance, and risk management with production and distribution. It is important to manage risks to avoid foodborne illness, expensive recalls, and loss of consumer trust. Risk management software has become more prevalent as an important tool for industry participants to manage their processes more effectively, ensure compliance, and reduce risks. In the article, we will consider the best solutions of risk management software developed for the food and beverage industry. We outline the key features, benefits, and basic considerations while choosing the right software.

What is Risk Management Software?

Risk management software is technological software designed to assist an organization in identifying, quantifying, and most importantly, proactive management of potential risks. Within the food and beverage industry, it is quite imperative because of the strict safety and regulatory standards that should be upheld to ensure the safety of the products for consumption by the public.

Definition and Purpose

Risk management software automates and streamlines all procedures and processes involved in assessing and mitigating risks. It mainly enables a business to manage potential risks in a proactive way, as it provides the business with tools for hazard identification, assessing their potential impact, and applying proper control measures.

All these features are embedded in the software to help in the whole process of risk management, including:

- Hazard Identification: Tools to detect and document potential biological, chemical, and physical hazards in the production process.

- Risk Assessment: Systems to evaluate the likelihood and severity of identified risks, enabling prioritization based on their potential impact.

- Control Measures: Features to implement and monitor control measures to mitigate identified risks effectively.

By using risk management software, companies in the food and beverage industry can ensure that they meet regulatory requirements, maintain high standards of food safety, and protect their brand reputation.

Importance of Risk Management in the Food and Beverage Industry

Risk management in the food and beverage industry is part of the pedestal upon which the industry stands. The food and beverage industries give prime consideration to the safety of the goods towards consumption and the quality standards that need to be met. The issues that need to be faced are many, from stringent regulation requirements to foodborne illness and sustained consumer confidence.

Regulatory Compliance

This is something that regulatory agencies—the FDA and food safety authorities at the EU level—are simply compelling companies to do. Risk management software automates enterprises' efforts to stay compliant, keeping track of regulations and ensuring all company practices meet up to standard.

Ensuring Food Safety and Quality

Safety in food is a non-negotiable factor. Risk management software helps a business identify possible hazards, conduct frequent inspections, and put in place the best preventive measures so that products are safe for consumption. This not only ensures protection to the consumers from hazardous intake but also safeguards the reputation of the company.

Preventing Foodborne Illnesses and Recalls

Effective risk management can prevent outbreaks that may impact public health negatively and lead to enormous losses for the company. The software keeps track of risk from supply to consumption and reduces contamination and product recall.

Risk management in the food and beverage industries is very essential because of the requirement to keep up high standards of quality, protection of consumer health, and compliance with regulatory provisions. With the help of advanced software solutions, enterprises will be much better equipped to handle potential risks and protect their operations.

Key Features of the Best Risk Management Software for Food and Beverage Industry

In the dynamic and highly regulated food and beverage industry, effective risk management software must encompass a range of sophisticated features to ensure product safety, regulatory compliance, and operational efficiency. Here are the essential features:

1. Comprehensive Compliance Management

Navigating the complex web of food safety regulations across different regions is a daunting task. The ideal software should provide:

- Regulatory Database: A centralized, constantly updated repository of local and international food safety regulations.

- Automated Compliance Checks: Tools that automatically verify that your processes and products meet the required standards, reducing the risk of non-compliance penalties.

- Audit Trails: Detailed logs of all compliance-related activities, ensuring transparency and accountability.

2. Real-time Monitoring and Predictive Analysis

Proactive risk management is key to preventing issues before they arise. Key functionalities should include:

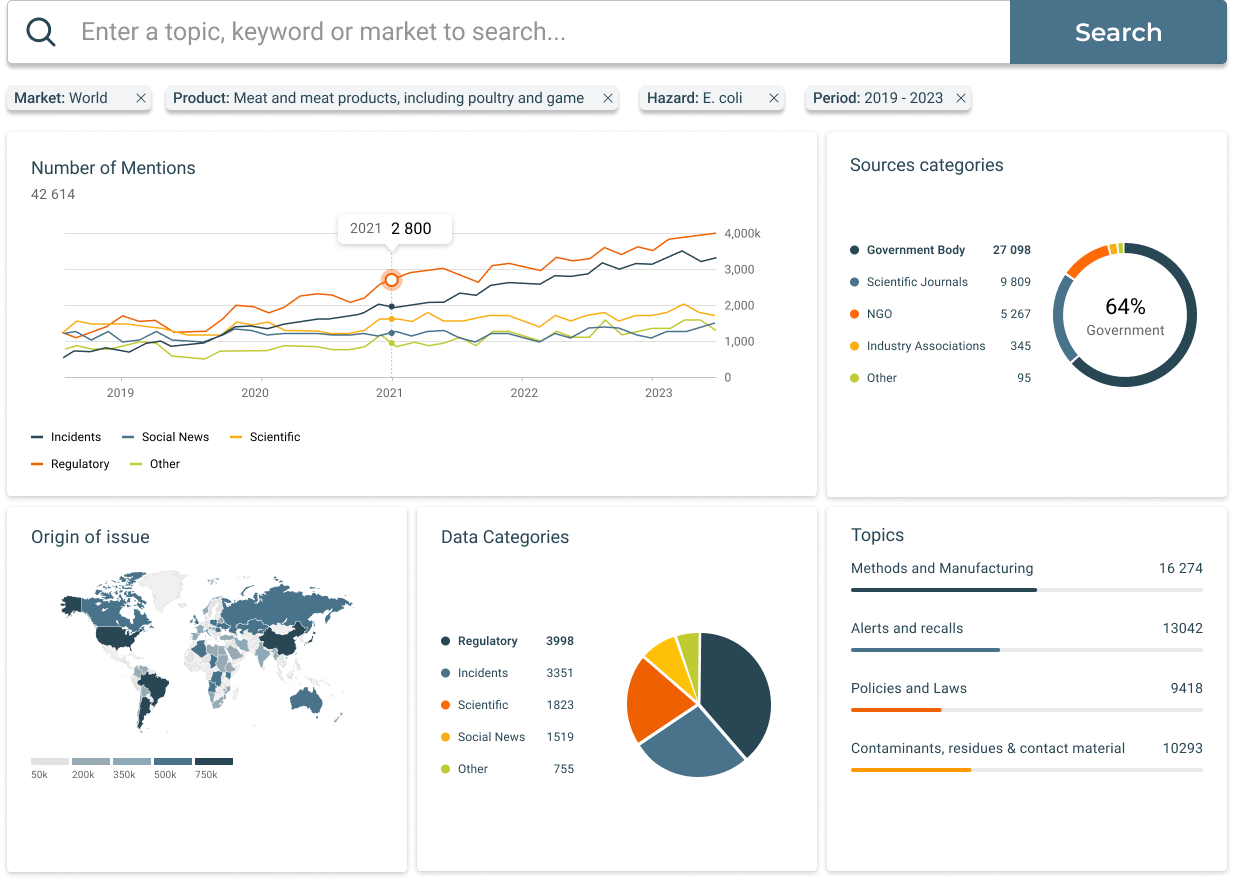

- AI-Powered Monitoring: Continuous surveillance of operations using artificial intelligence to detect deviations from safety protocols in real time.

- Predictive Analytics: Advanced algorithms that analyze historical and real-time data to forecast potential risks, allowing companies to take preventive measures.

- Instant Alerts: Immediate notifications for any detected anomalies or potential hazards, enabling swift corrective actions.

3. HACCP (Hazard Analysis and Critical Control Points) Support

Ensuring food safety through the HACCP system is crucial:

- Hazard Identification: Tools to systematically identify potential biological, chemical, and physical hazards in the production process.

- Critical Control Points Monitoring: Continuous monitoring and documentation of critical points in the production line where hazards could occur, ensuring they remain under control.

4. Incident Tracking and Reporting

Effective management of food safety incidents is essential to minimize impact:

- Incident Logging: Detailed recording of all incidents, including their nature, cause, and corrective actions taken.

- Trend Analysis: Analyzing incident data to identify patterns and prevent future occurrences.

- Regulatory Reporting: Generating reports that comply with regulatory requirements for documenting and reporting food safety incidents.

5. Centralized Document Management

Managing vast amounts of documentation is simplified with:

- Document Repository: A secure, centralized location for storing all food safety-related documents, making them easily accessible and manageable.

- Version Control: Keeping track of document revisions to ensure the use of the most current and accurate information.

- Collaboration Tools: Enabling multiple stakeholders to access, review, and edit documents simultaneously.

6. Comprehensive Risk Assessment and Mitigation

Assessing and mitigating risks is at the core of risk management:

- Risk Assessment Tools: Systematic evaluation of the severity and likelihood of identified risks, prioritizing them based on their potential impact.

- Mitigation Strategies: Implementing and monitoring strategies to reduce or eliminate identified risks, ensuring continuous improvement in food safety practices.

7. Supply Chain Management

Ensuring the safety and quality of ingredients and products throughout the supply chain:

- Supplier Risk Assessment: Evaluating the risk level of suppliers based on their compliance history and quality performance.

- Traceability: Tracking the origin and journey of ingredients and products from suppliers to consumers, ensuring quick identification and isolation of potential issues.

8. Advanced Analytics and Reporting

Data-driven insights are crucial for informed decision-making:

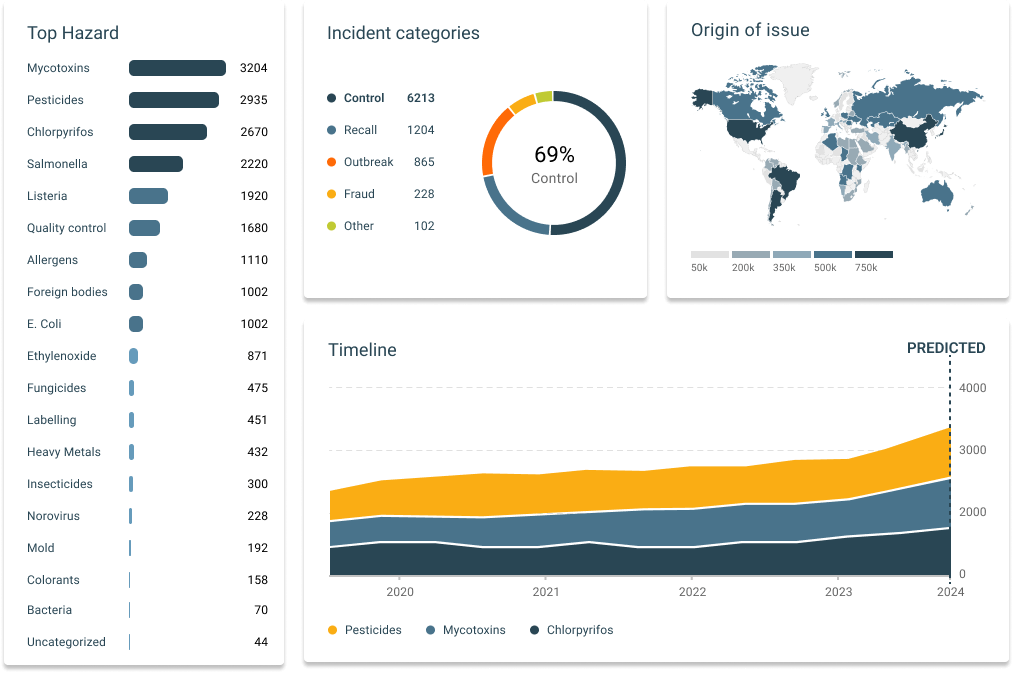

- Customizable Dashboards: Providing a visual overview of key risk indicators and compliance status.

- Detailed Reporting: Generating comprehensive reports that highlight trends, potential risks, and areas for improvement.

- Data Integration: Integrating data from various sources for a holistic view of food safety and compliance.

9. User-friendly Interface and Training

The software should be accessible and easy to use for all employees:

- Intuitive Interface: Simplifying navigation and operation of the software.

- Training Modules: Providing thorough training resources and support to ensure effective use of the software.

By incorporating these features, risk management software can significantly enhance food safety, streamline compliance efforts, and improve overall operational efficiency in the food and beverage industry. Investing in such robust software is crucial for maintaining high standards and ensuring consumer trust.

Leveraging SGS Digicomply for Comprehensive Risk Management

Risk management is a key factor in product safety, along with compliance and operational efficiency in the food and beverage sector. In this regard, SGS Digicomply is a robust platform comprising a range of features designed to serve those needs. The following sections detail how some of its key functionalities enhance risk management.

Regulatory Intelligence Hub

The Regulatory Intelligence Hub comprises an updated repository for standards and requirements from over 150 jurisdictions, easing companies' compliance with access to regulatory information in ways through which companies are able to adapt easily to new regulations and sustainable compliance to prevent legal risks. It also features an AI Copilot—think of it as something like a GPT assistant that enables users to ask questions in common language and receive answers backed with sources to make compliance management more efficient and accurate. Explore these demos to see how it works

Food Safety Intelligence Hub

This feature utilizes AI to combine data from numerous sources, offering deep insights into food safety trends and emerging risks. By providing a detailed analysis of potential hazards, the Food Safety Intelligence Hub enables proactive risk management, helping companies identify and address issues before they escalate. Explore these demos to see how it works

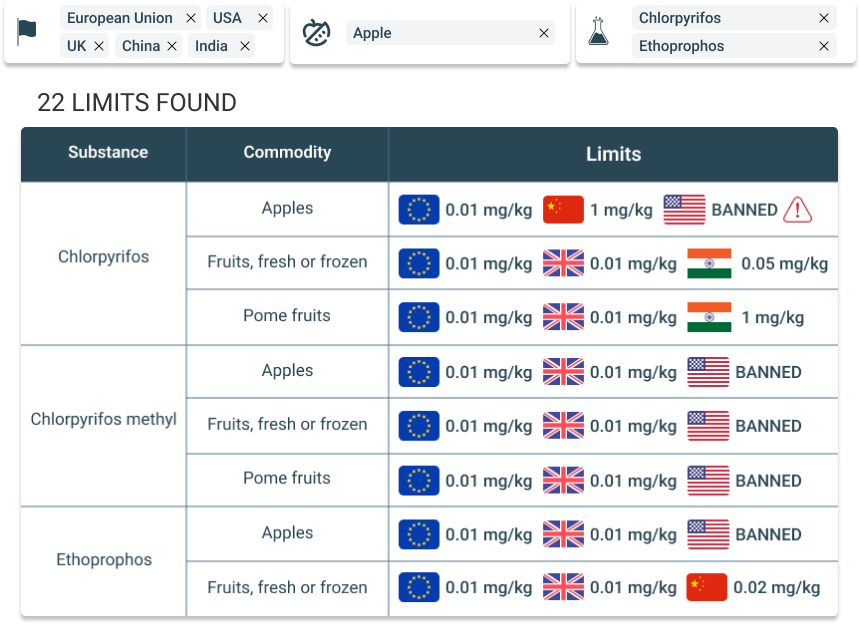

Global Ingredient Monitor

The Global Ingredient Monitor allows companies to track legal limits for residues, usage, and banned substances globally. This tool ensures that all ingredients used in production comply with international standards, reducing the risk of non-compliance and enhancing product safety. Explore these demos to see how it works

Horizon Scanning

Horizon Scanning monitors supply chain dynamics to identify potential risks related to ingredients and suppliers. It helps companies stay ahead of biological, chemical, and physical hazards, emerging threats, and regulatory changes, enabling them to implement preventive measures effectively. Explore these demos to see how it works

SGS Digicomply provides an end-to-end suite of features necessary to enable effective risk management in the food and beverage industry, including extensive regulatory databases, AI-driven food safety insights, global ingredient monitoring, and proactive horizon scanning to make sure that the best possible level of safety and compliance is in place. Automated compliance checks and efficient workflows for labeling drive this further.

Explore SGS Digicomply demos to see how these features can enhance your risk management strategies.

.webp?width=1644&height=1254&name=Food%20Safety%20Dashboard%201%20(1).webp)