If you work with plastic materials intended to come into contact with food in the EU, it’s time to pause. The new Commission Regulation (EU) 2025/351, adopted in February 2025, is not just a minor amendment—it’s a systemic overhaul. This regulation affects virgin plastics, recycled materials, and even GMP practices. For QA, compliance, and regulatory teams, it’s the most significant update in a decade.

The Shift: From Layers to Materials

For years, Regulation (EU) 10/2011 has focused on "plastic layers." But in reality, many food contact plastics are complex 3D structures without clear layer delineation. This created ambiguity. The 2025/351 regulation clarifies: compositional rules now apply to the entire material, not just individual layers. This subtle wording shift has major downstream implications for how compliance is assessed—especially in laminated, printed, or coated products.

Insight: Many manufacturers still operate under legacy interpretations. If your technical dossier separates plastic from adhesives, inks, or varnishes without linking them through migration modeling—you’re already behind.

Reprocessed Doesn’t Mean Recycled

The new regulation formally separates reprocessed by-products from recycled plastics (governed under Regulation 2022/1616). Offcuts and scraps reused in the same facility? That’s reprocessing—and it must meet new purity and documentation rules.

What’s new? You’ll now need to prove that by-products are collected uncontaminated, traceable, and not mistaken for recycled waste. GMP documentation will require exact identification and use instructions for each batch.

Real-world challenge: Many recyclers don’t currently distinguish between reprocessing and recycling in their batch traceability systems. This creates a blind spot for auditors—expect it to be a focus area in 2027 inspections.

Purity Goes Quantitative

The phrase “high degree of purity” now has a measurable backbone. The updated Article 3a defines specific migration thresholds—0.00015 mg/kg and 0.05 mg/kg—to determine when genotoxicity testing is required.

Why this matters: Previously, impurity evaluations were often subjective. Now, if your non-intentionally added substances (NIAS) aren’t risk-assessed or don't meet purity specs from Annex I, you’re potentially in violation—even if migration is low.

Tip: Don’t wait for EFSA rejections. Start applying group genotoxicity assessments to UVCB substances (those of unknown or variable composition) if you use materials from natural origins or biological sources.

Repeated Use ≠ Infinite Safety

With the push toward reusables (under the Single-Use Plastics Directive), plastic FCMs are seeing more lifecycle exposure. But repeated use can degrade material performance and increase migration—especially with acidic or fatty foods.

New obligation: Manufacturers must provide explicit use instructions to prevent misuse (e.g., high-temperature microwave use) and identify visual indicators of material fatigue like yellowing, cracking, or loss of gloss.

QA takeaway: Your declaration of compliance now needs to do more than confirm compliance—it must educate users. This is especially relevant for B2B food service products where repeated use is frequent, and user training is minimal.

Not Just What You Add—But What’s Left Behind

Perhaps one of the most overlooked changes is the expanded scope of the Declaration of Compliance. It now must include:

-

NIAS if they could cause non-compliance with Article 3 of Regulation 1935/2004

-

Confirmation of substances made from waste

-

Instructions for reprocessing by-products

This turns the DoC into a living technical file, not a one-off statement.

Implementation insight: Expect upstream suppliers (resin producers, additive suppliers) to push back on disclosure. You may need NDAs just to comply with traceability requirements.

Final Word: Timeline and Risk

The transition period is 18 months—until September 16, 2026. But critically, starting December 16, 2025, any non-compliant intermediate products must be flagged as such and cannot be used beyond the deadline.

The most forward-looking companies are already adapting their quality systems, updating migration models, and revalidating supplier declarations. The rest risk being caught off guard during audits—or worse, facing product recalls.

Official Source: EUR-Lex – Regulation (EU) 2025/351

Effective Date: September 16, 2026

Markets Affected: EU Member States

Related Regulations: 10/2011, 2022/1616, 2023/2006, 1935/2004

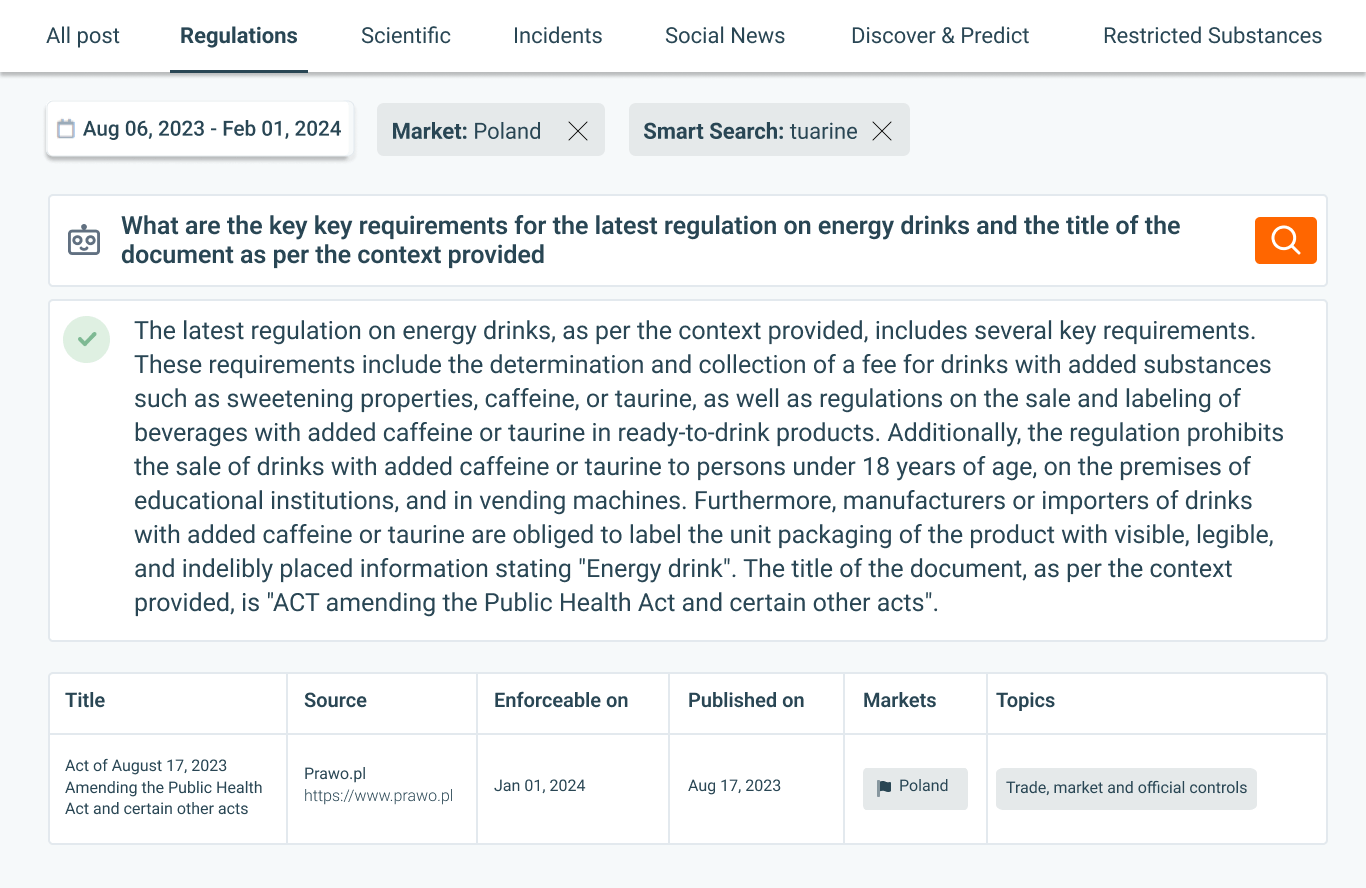

Explore SGS Digicomply’s Regulatory Intelligence Hub

SGS Digicomply’s Regulatory Intelligence Hub offers a powerful solution for managing regulatory complexities across 150+ jurisdictions. With AI-driven research tools, easy-to-read regulatory guides, change monitoring, and an interactive agenda, the platform empowers teams to make informed, timely decisions. Whether you’re tracking new rules or comparing global standards, SGS Digicomply is your essential partner for proactive compliance. See how it works in our demo.

.webp?width=1644&height=1254&name=Food%20Safety%20Dashboard%201%20(1).webp)