Ethylene oxide (EO) has become one of the most closely monitored substances in global food trade — especially when it comes to spices. What was once a technical detail in regulatory databases is now a frequent topic in recall reports, customs alerts, and supplier audits. For professionals in regulatory affairs, quality assurance, and procurement, understanding the actual legal limits for ethylene oxide in the EU is not just helpful — it’s essential.

In this week’s Global Ingredient Monitoring, we take a closer look at how EO is regulated in spices under European law, based on official documents and current maximum residue levels (MRLs). No speculation, no outdated interpretations — just what the legislation says today.

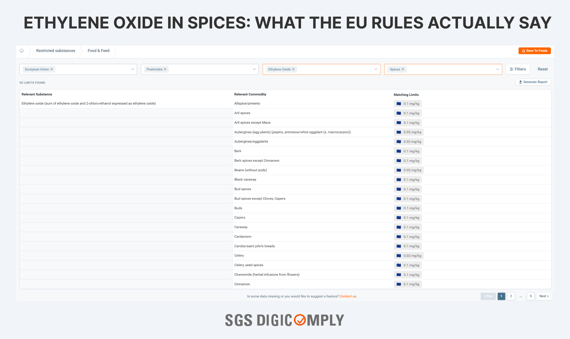

A complete and filterable database with global regulations —including maximum levels, analytical requirements, and product-specific rules—is available to SGS Digicomply users. Feel free to explore the Global Ingredient Monitor demo and try this tool in action.

One Limit, Two Substances

In the EU, ethylene oxide is not regulated on its own. The legal residue definition combines two substances:

Ethylene oxide (sum of ethylene oxide and 2-chloroethanol expressed as ethylene oxide)

This matters. Even if EO is not detected in a spice sample, the presence of its metabolite — 2-chloroethanol (2-CE) — still counts toward the legal limit. Laboratories are required to analyze both, and sum the results as if they were entirely ethylene oxide. This strict approach reflects the EU’s classification of EO as a genotoxic carcinogen and its zero-tolerance position on avoidable contamination.

2-Chloroethanol often enters the picture unintentionally. It can be present due to EO fumigation, but it may also appear as a degradation product or through contact with materials or surfaces previously treated with EO. That’s why it’s not enough to avoid direct EO use — regulators expect manufacturers to account for residual 2-CE as well. Its presence, even in isolation, can be grounds for rejection if it pushes the combined residue value over the legal threshold.

The EU’s Official Limit for Spices

Under Regulation (EC) No 396/2005, as amended by Commission Regulation (EU) 2015/868, the EU has set the maximum residue level for ethylene oxide in spices at:

0.1 mg/kg, measured as the sum of EO and 2-CE, expressed as EO.

This limit is applied to all spices grouped under Annex I, code 0800000, which includes black pepper, chili, paprika, coriander, nutmeg, turmeric, cinnamon, and others. The 0.1 mg/kg value is marked with an asterisk in the legislation, meaning it corresponds to the limit of quantification (LOQ) — the lowest level that can be reliably detected and measured in a lab.

In practical terms, this means the EU expects no detectable ethylene oxide contamination above trace levels in spices. Anything higher than 0.1 mg/kg is treated as non-compliant — regardless of whether it was EO itself or just 2-chloroethanol.

The current MRL has been in place since 30 June 2015, and remains unchanged. All enforcement actions, border controls, and compliance assessments are based on this threshold today.

What It Means for Importers and Manufacturers

For companies sourcing or exporting dried spices to the European market, these rules introduce a high bar for compliance. Ethylene oxide is sometimes used as a sterilizing agent in producing countries, particularly to reduce microbial loads in dried botanical ingredients. However, the EU does not recognize this use and does not permit residues to remain in the final product — no matter the justification.

Many recent border rejections and product recalls have been triggered not by direct EO use, but by residual 2-CE, which can linger in ingredients that were treated, stored, or transported in facilities using EO. The strict residue definition means even low levels of 2-CE — if not properly explained or removed — can render a shipment non-compliant.

That’s why ingredient compliance today isn’t just about COAs. It’s about understanding how EO residues behave in real matrices, how to interpret lab reports that include both EO and 2-CE, and how to ensure supplier protocols match EU regulatory expectations.

Access the Full Picture with SGS Digicomply

This article focuses on EU requirements, but ingredient compliance is a global challenge. Regulatory limits, analytical definitions, and residue tolerances vary dramatically across markets — from the United States to China, South Korea, Singapore, and beyond.

A complete and filterable database with:

-

Global maximum residue levels

-

Analytical requirements and residue definitions

-

Ingredient-specific regulatory rules

-

Direct links to official texts and government sources

is available to all SGS Digicomply users. This includes access to the full Global Ingredient Monitoring module, which allows you to filter by chemical, ingredient category, and region — all in one intuitive interface.

Feel free to explore the Global Ingredient Monitor demo and try this tool in action.

Final Takeaway

The EU’s position on ethylene oxide in spices is clear: only trace-level contamination is acceptable — and that includes 2-chloroethanol. Anything above 0.1 mg/kg (as EO) is a regulatory violation. There are no exceptions based on origin, function, or historical use.

Understanding this rule — and how it’s measured in real-world testing — is essential for protecting your brand, your supply chain, and your customer trust.

SGS Digicomply helps make that understanding actionable.

.webp?width=1644&height=1254&name=Food%20Safety%20Dashboard%201%20(1).webp)